Prepare Purchase Requisitions very carefully. Even the smallest error that often creeps in inadvertently could cost thousands of rupees by way of delayed deliveries, wrong useless supplies, and other expenses. Case Studies in this article discuss and illustrate these aspects.

Word Purchase Requisitions Clearly in simple language

Wording Purchase Requisitions (PR) clearly, in simple language, and offering scope to the vendor to suggest alternatives develops best and most economical quotations soonest by eliminating needless clarifications. The same applies to Purchase Orders (PO) also. In addition, it prevents wrong deliveries too. The case studies that follow illustrate these principles::

Case Study 1: PR for Leak Tight Control Valves

The author found that the process licensor had wrongly selected high leak 0.5% leak class double seat CVs valves for the three vent applications of his ammonia plant. These large CVs – one of 8” and 2 more of 6” – leaked enormous quantities of expensive reformed gas (RFG) estimated to cost the plant over Rs 10 million annually. His proposal to replace the leaky valve body assemblies (VBA) with more leak tight valves advertised by a famous CV manufacturer was not well received, perhaps due to the project (Piping, Instruments & Drawings (P&ID) managers overlooking this during the project stage. The author persisted and demonstrated the high air leak by a bench test during a short plant shutdown due to other problems. The group accepted his appeal to listen to his detailed explanation in a meeting: he explained that the permitted bench test leak for the double seat CVs is 0.5% of the valves full rated flow capacity which is around 1.5 times that of 100% production flow rates. In addition, because of the differential thermal expansion of the carbon steel body and SS trim the leak would be much more than the bench tested 0.5% leak. Hence, practically speaking, the leaks would be around 1% of the valves max flow rates under service conditions. The three valves chosen for 150% of max production flow rates obviously leaks around 4.5% of rated production flow RFG – an enormous waste indeed. The dazed, but somewhat convinced managers accepted his proposal and approved replacing the valve bodies.

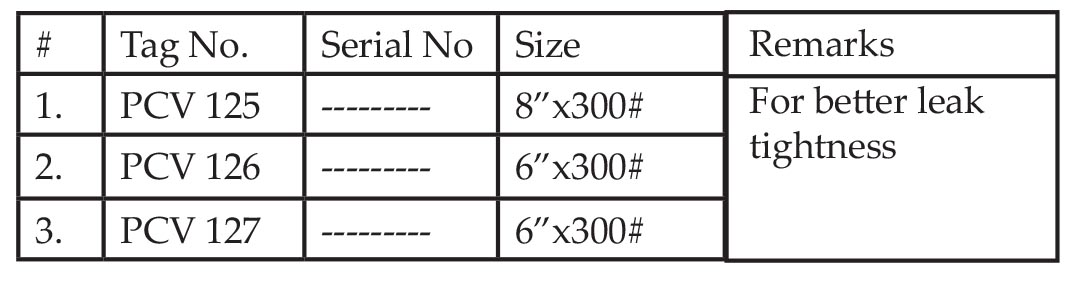

Attachment to his PR was as under:

“Replacement leak tight soft seat valve body assemblies to assemble on to the existing actuators of previously supplied control valve + actuator assemblies. Other conditions are the same as in previous PO.

After a month the vendor replied that soft seat valve bodies to use with existing actuator and to suit the service conditions are not available. After protracted 6-months long, back and forth correspondence the vendor quoted 0.01% leak class Balanced Plug Valve Body assemblies for PCV 126 and 127 for mounting on to the existing actuators, and a full valve + actuator assembly for PCV 125 as a larger actuator was necessary.

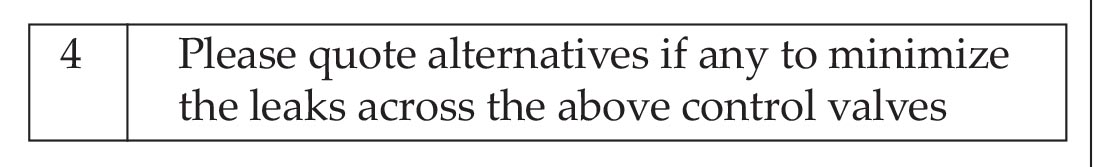

Had the author added the below given row 4 in the

PR in the very beginning, the protracted correspondence and its associated expenses, six month replacements arrival delays and almost `5-million worth leak losses could have been eliminated. Post new valve installation specific consumption figures confirmed around 2% loss due to leaks. The management too should have encouraged the author and approved his proposal sooner to realize the benefits.

Case Study 2: Encourage Vendors to offer alternatives also:

The compelled to buy indigenous Ammonia tank vapor recovery system’s less than 20% availability despite enormous maintenance efforts and expenses resulted in around 500 kg/hour of ammonia venting. Besides the astronomical sums of money loss, environment regulations threatened factory closure.

The tired author made a plant engineer develop specifications and raise a PR for importing compressors to replace the indigenous ones which were the problems’ root cause. Having learnt from case study 1 the author included the below given in all PRs:

1. Vendors’ alternative offers if any are welcome

2. Pl furnish few users addresses

3. Please furnish specifications of motors > 50 KW if any for indigenous purchase.

A US vendor offered a skid mounted plant less motor and few user addresses, instead of the 4 Nos. of piston compressors, at a marginally higher price. The users confirmed the skid worked and in fact it was ‘fit & forget’!

The package though marginally of a higher price was indeed a worthy purchase with the below listed advantages:

1. Bolted on the readied foundation it went on line within two days of arrival

2. It accepted the surplus 450 HP, 3000 RPM, 3.3 KV motor

3. Zero ammonia venting paid the cost of the package within two weeks

4. Saved factory closure by pollution authorities

5. It was indeed a fit & forget device as a user assured

Keying in errors can kill! Despite enormous care in keying in requirements in PRs the practice of keying in * to select mode choices and similar items leads to costly mistakes and wasted money as Case Studies 3 and 4 of the bygone typewriter days show:

Case Study 3:

An engineer wrote 16”x300# Carbon Steel Gate Valve on a paper and handed it to a typist along with a page of preprinted specifications sheet to type out a PR. The typist inadvertently typed it as 18”x300#. The engineer too missed it while signing the PR and it reached the foreign purchase agent. Fortunately the buyer of the foreign agent questioned back, “do you really want 18”x300# gate valve? Plants rarely use 18” pipelines; they use either 16 or 20”. This wise feedback alerted the engineer and he found he too had missed the typo error, when he signed the PR. He sent General Manager signed appreciation letter to the foreign agent’s buyer profusely thanking him for the timely caution and him going beyond the call of duty. The buyer could have just processed the item mechanically and the company would have lost over `2 lakhs (1980 figures); in addition the project for saving `5 lakhs yearly for which the 16” valve was needed would have been delayed by 6 months or more.

Case Study 4

The author raised a PR for a Super-Efficient Moisture Separator (SEMS) for improving the performance of a huge centrifugal compressor for saving millions of rupees yearly. Since that was required during the TA scheduled 18 months hence, he had specified ‘sea freight’.

The warehouse person informed the author SEMS arrival 6-months later and requested him to draw from the stores within 3 days, as non-compliance report goes to the Managing Director. The information that the equipment weighing 6 T has come by air at higher than normal sea freight rates shocked the author. His and the buyer’s PO copy showed the *in the sea freight boxes! However, the vendor sent PO copy showed the* in the air freight box shown thus:

Ocean □ Road □ Air □ Rail □

A simple error has caused a great loss! The plant revised the PO thus: Mode of shipment ————– (Ocean, Air, Road, Rail; Type the proper word in the line).

Fortunately, the SEMS installed at the next opportune shutdown, performs better than vendor guarantee and saved lot of money year after year.

Consolidate Requirements of large parts to avail quantity discounts:

A huge refinery saved enormous amounts by this method. They consolidated the specifications of Electric Motors, couplings, and Mechanical Seals gathered from more than 2000 pumps from vendors and raised a PO for each of the entire lots from Motor, Mechanical Seal and Coupling Vendors, and saved around 10% costs. They instructed the Motors, Mech Seal and Coupling vendors to send the products to the different pump vendors who assembled these as needed. They followed similar practices for purchasing other common items and saved huge sums.