Introduction

Chemical production is mostly a complex process that consists of many unit processes and unit operations, as is well known. Chemical engineers have to design chemical processes based on the desired end product. This involves monitoring and controlling many process parameters such as pH, temperature, pressure, flow, the concentration of liquid chemicals or gases for further product development.

Chemical production processes could be continuous or batch type which need precise control of process parameters for desired quality. Currently, midsegment chemical industries mainly monitor and control a few parameters such as temperature, pressure, pH, etc which are important for quality control but liquid (chemicals & solvents) & gas flow measurements are often not given that importance. But this in turn compromises fine quality control.

Importance of Precise Flow Measurement

Flow measurement in chemical industries is now becoming crucial for good quality control and conservation of energy. Various chemical processes demand accurate flow measurements as below :

● Solvent & Gas precise dosing into reaction vessels

● Mass transfer processes

● Process gas emission control

● Inert gas tank blanketing for safety

● Flare gas monitoring and control

● Gas, steam, fuel gas, compressed air utility flow monitoring

Precise gas flow measurement is becoming crucial in chemical & fine chemical pilot plants and production processes for high-quality product manufacturing.

Pros & Cons of Various Flow Technologies

Various Flow technologies available for Gas flow monitoring and control are :

a) Orifice Type Flow Meter – Differential pressure measurement across restriction orifice design

Pros :

● Volumetric flowmeter, Oldest, and rugged technology design as per ISO5167/BS1042

● Rugged construction designed for high pressure & temperature applications

● Can manufacture with different grades of metals for corrosive gases

Cons :

● High-pressure drop

● Low accuracy

b) Coriolis Mass Flow Meter – Works on oscillating tube frequency measurement direct mass flow measurement design

Pros :

● Direct Mass flow rate, proven high accuracy, and true mass flow measurement

● Very high accuracy and repeatability

● A few metal construction possible for corrosive gases

Cons :

● High-pressure drop

● High initial cost

● Works up to 100oC temperature

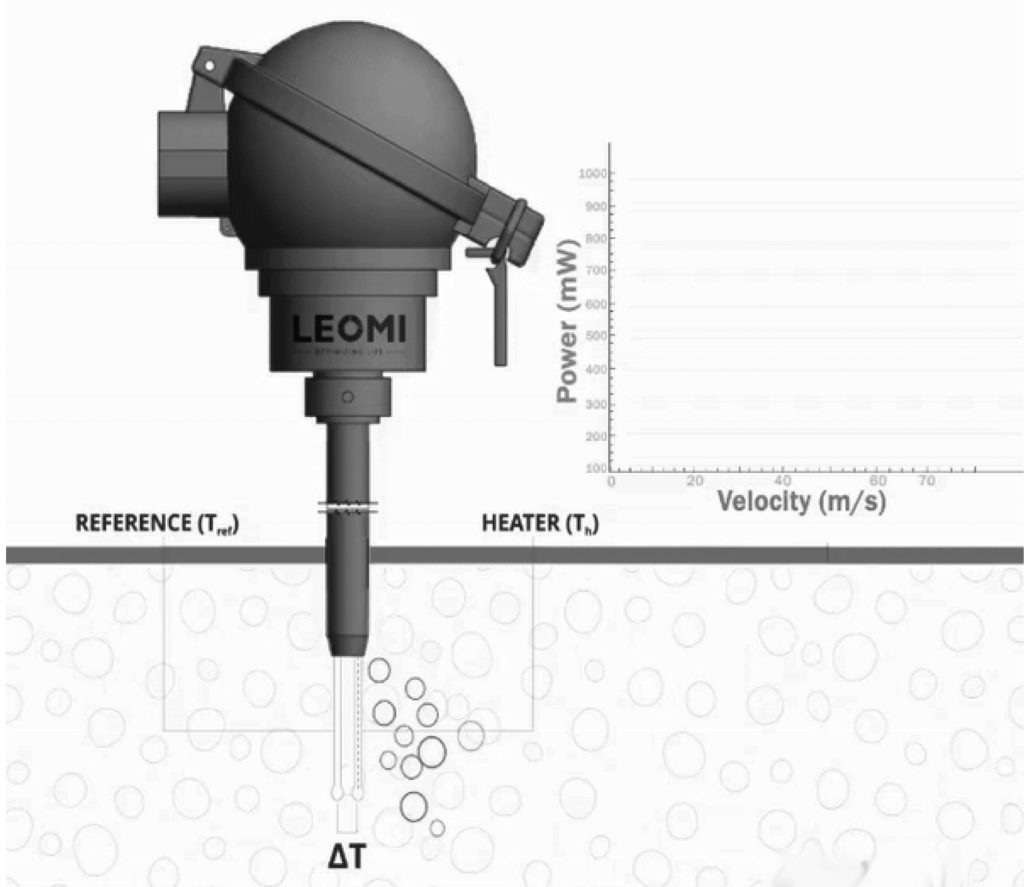

c) Thermal Mass Flow Meter – Heat dissipation principle

Pros :

● Mass Flow rate independent of pressure and temperature.

● No pressure drop

● High turndown ratio ( 100:1) & high sensitivity for leak detections.

● Various MOC suitable for corrosive gases possible

● Easy installation and low maintenance

Cons :

● Not suitable for high moisture content

● Sensitive to dust concentration, needs cleaning

d) Vortex Flow Meter – vortices low-pressure pulse frequency measurement principle

Pros :

● Volumetric Flow rate

● Works for high pressure and temperature applications such as gas, water & steam.

● Better accuracy & 10:1 turndown ratio

Cons :

● Sensitive to vibrations & moisture content

● Not suitable for higher pipe diameters above 200mm

● Installation is critical

e) Ultrasonic Flow Meter – Transit time difference of sound velocity in the fluid

Pros :

● Volumetric Flow rate measurement

● No pressure drop

● High turndown ratio ( 20:1)

● Non-contact easy in any moc pipeline for corrosive gases possible

Cons :

● Not suitable for high moisture content

● Low accuracy

● Internal pipe conditions affect measurement accuracy

● High initial cost

f) Turbine Flow Meter – Rotating turbine frequency measurement

Pros :

● Volumetric flow rate measurement.

● Low cost

Cons :

● Moving parts periodic maintenance needed

● Not suitable for high moisture content

● Low accuracy

The pros & cons of various flow measurement technologies, as highlighted above might help chemical industry instrumentation engineers to select a flow technology that suits them best. Current trends show the emerging role of Thermal Mass (Calorimetric) flowmeters in chemical industries which provide many benefits in various chemical process applications.

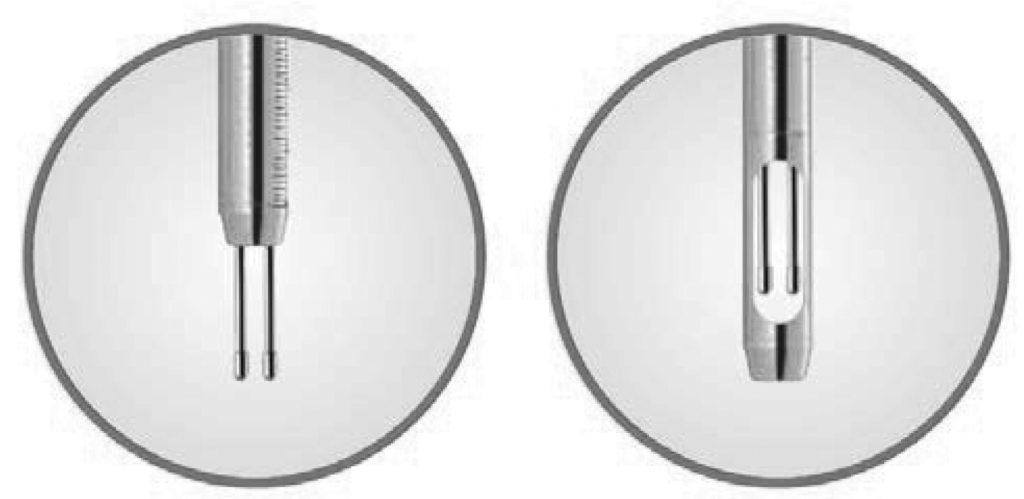

Thermal Mass Flow Meters

The latest innovation from various manufacturers of thermal mass flowmeters provides benefits to chemical industries as below :

● Measures mass flow rate accurately even in wet gas effectively

● Long life & rugged sensor insensitive to dust and dirt

● Special sensor or PFA Coated for highly corrosive gases

● Highly sensitive for leak detections can provide good knowledge of process fluctuations.

● Saves energy while monitoring with no pressure drop

● Online Sensor removal is possible without interruption of the process

● Accurate measurement over entire temperature range up to 400°C applicable

● Versatile & Adjustable for various pipe dimensions

● Easy and cost-effective installation even for large pipe sizes

Conclusion

Thermal mass flow technology is gaining ground in chemical industries for process gas emissions at low pressures and chemical pilot gas flow measurement needs for research.