Advertisement

Abstract

Energy transition and industrial sustainability involve the monitoring, control and disclosure of industrial operations aimed at reducing greenhouse gas emissions and addressing Environmental, Social, and Governance (ESG) concerns. It encompasses various areas, including energy efficiency, transitioning to net-zero emissions, decarbonisation, renewable power generation, grid infrastructure, renewable energy adoption, circular economy practices, responsible sourcing, and ESG reporting. These efforts are crucial in combating climate change and driving transformative technological advancements in industry.

Globally, we are in a critical time of action on climate change. Energy transition and sustainability are now being woven into the core fabric of business strategies of industrial companies, particularly manufacturing, utility, and oil and gas organizations. Efforts are often halting or grudgingly taken, and results have been mixed at best, but change has at least begun and will accelerate, mainly due to regulation and technological innovation. Both the 2021 United Nations (UN) annual climate change conference, COP26 (Conference of Parties) climate agreement and the latest Intergovernmental Panel on Climate Change (IPCC) report call for action on climate change pointing to irrefutable degradation across the Earth’s climate system, atmosphere, oceans, ice floes and on land. This, combined with a shift in corporate mindsets following the past two years of pandemic, is reshaping industry, sparking innovation, and accelerating transformational technological change throughout the sector. COP26 has arguably resulted in the most ambitious international climate agreement to date. Though we still can expect to see 2.4oC warming, all participating nations did agree to return to COP27 with more aggressive goals.

Energy transition and industrial sustainability refers to the management, tracking, and reporting of industrial activities targeting GHG reductions and Environmental, Social, and Governance (ESG) issues. Industrial sustainability covers a range of topics such as energy management and efficiency, net-zero transition, decarbonization, power generation, grid transmission and distribution, renewable energy electrification, circular economy, ethical sourcing, ESG reporting, and more.

Emissions Measurement

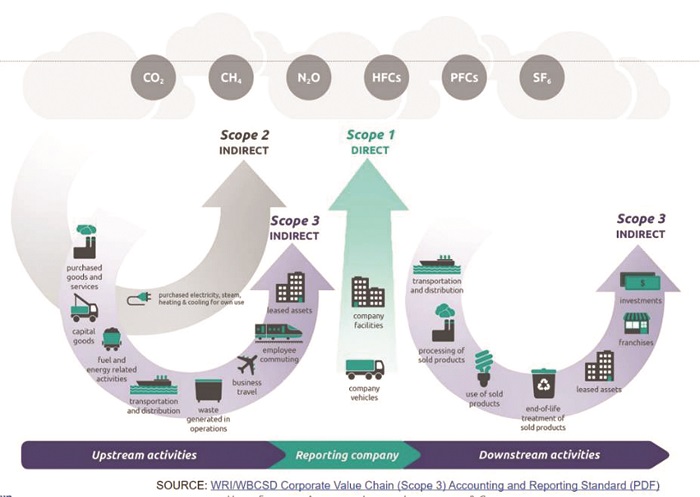

Historically, one of the major hurdles to sustainability was agreement across stakeholders and interests as to how to view emissions so that they could be classified in a way that allowed improvement protocols, standards, and metrics to be quantifiably measured. Around the turn of the century, the GHG Protocol was developed by the World Resources Institute (WCI) and World Business Council for Sustainable Development (WBCSD) as a means of defining emissions. Over the course of more than a decade, that definition evolved, leading to what is now the world’s most widely accepted accounting and reporting standards for measuring GHG emissions. Emissions are classified as follows:

• Scope 1: Emissions directly from owned and controlled company sources, such as production facilities and transportation vehicles.

• Scope 2: Emissions from facilities that provide energy that is bought and consumed by a company.

• Scope 3: Emissions that originate outside of the company, such as from other companies in the supply chain or end users.

These scopes come into more focus when visualized through the many mechanisms that are familiar to us all as consumers. The graphic provided by WRI and WBCSD (Fig 1) illustrates the overlapping nature of the gases that make up the emission scopes.

These scopes come into more focus when visualized through the many mechanisms that are familiar to us all as consumers. The graphic provided by WRI and WBCSD (Fig 1) illustrates the overlapping nature of the gases that make up the emission scopes.Embedded, Operations, and Live Use GHG Emissions

Industrial companies can usually identify the various sources of GHG emissions arising from their operations – though tracking and managing those emissions may not be at all straightforward. These are emissions generated from daily operations, such as production activities, heating and cooling buildings, operating company vehicles, and the like. It can be helpful to consider embedded (upstream) GHG emissions and live use (downstream) GHG emissions as well. Customers and other stakeholders increasingly want to know a product’s carbon footprint, which necessitates understanding the embedded GHGs, as well as the emissions generated while using the product, which necessitates understanding the live use GHGs.

Adopting a Responsible Approach

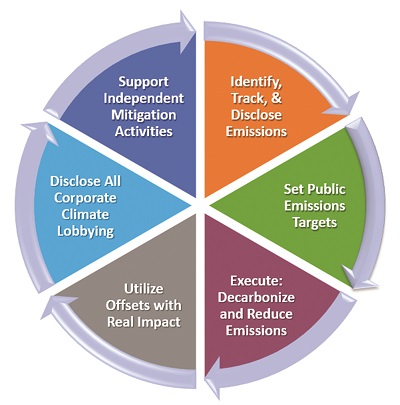

A responsible approach to climate mitigation involves six key activities (See Fig – 2). First, aggressively seek out and identify GHG emissions – especially those types requested by stakeholders – and disclose the current state. Next, establish public emissions targets, and plan how to meet them, delineating the incremental steps that will unavoidably be necessary. Execute on the plan, decarbonizing where possible and obvious, increasing efficiencies, and reducing emissions. Report progress regularly. Use carbon offsets as a bridge step where necessary to meet your goals, but ensure that the offsets used are quantifiably effective, traceable and have a measurable and positive impact on GHG reductions. Planting trees that you later harvest for use in production is not as good as planting elsewhere. Publicly commit to aligning all climate change lobbying with the goal of restricting global temperature rise to 1.5⁰ C above pre-industrial levels and disclose all climate lobbying activities. Another potential tool is making contributions or otherwise supporting independent climate mitigation activities, acting outside your value chain.

A responsible approach to climate mitigation involves six key activities (See Fig – 2). First, aggressively seek out and identify GHG emissions – especially those types requested by stakeholders – and disclose the current state. Next, establish public emissions targets, and plan how to meet them, delineating the incremental steps that will unavoidably be necessary. Execute on the plan, decarbonizing where possible and obvious, increasing efficiencies, and reducing emissions. Report progress regularly. Use carbon offsets as a bridge step where necessary to meet your goals, but ensure that the offsets used are quantifiably effective, traceable and have a measurable and positive impact on GHG reductions. Planting trees that you later harvest for use in production is not as good as planting elsewhere. Publicly commit to aligning all climate change lobbying with the goal of restricting global temperature rise to 1.5⁰ C above pre-industrial levels and disclose all climate lobbying activities. Another potential tool is making contributions or otherwise supporting independent climate mitigation activities, acting outside your value chain.Sustainability Is More than GHG Mitigation

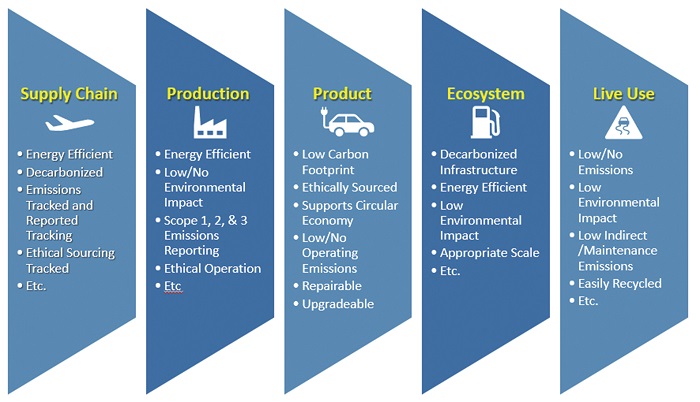

Reducing GHG emissions is crucial for the climate, but reducing emissions alone is not a sustainability strategy. Stakeholders must also focus on a company’s ESG goals and performance. It can be helpful to address overall sustainability goals in five areas: supply chain, production and operations, product, product ecosystem, and live use. These will all vary by industry, type of product, region, and a variety of other factors. A barrel of oil, an automobile, plastic, generated power, a tractor – obviously, these cannot be treated the same, so the distinct role each plays in sustainability must be considered.

Product

Customers and other stakeholders increasingly want products to have a low carbon footprint, and they expect it to be transparent to them. They want them to be built from ethically sourced materials and components. They want products that generate little or no emissions during their lifetime of operation. They want products that are maintainable, upgradable, and reusable, instead of disposable, planned obsolescence products.

Production and Operations

Here the expectations are already becoming clear – industrial companies are beginning to be held to account for sustainability. Companies are expected to decarbonize and operate efficiently and with low or zero emissions. Those operating at historical profitability will be held up to increasingly stringent accountability to become more sustainable.

Specific timelines to do so have been given. They are expected to track, manage, monitor, and report on ESG metrics. Where possible, they should move to a circular economy model, use ethically sourced materials and components, generate low or zero GHGs, sustain the local operating environment, and deliver products that are climate friendly. This will necessitate the use of software and AI, together with connected machines and workers, digitalization, automation, and introduction of new operating and business processes (see Fig 3).

Specifically, three industrial pillars—manufacturing, utilities, and oil and gas—are at the center of global energy transition and sustainability efforts. If these segments do not transform from their current role in the market, other efforts across the globe will ultimately be unsuccessful. When examining the challenges each faces, there are considerable nuanced similarities and differences. Additionally, there are dependencies across the three and even the potential for competitive conflict.

Oil and Gas Companies Need Capabilities for Reinvention

The oil and gas industry has its own unique characteristics related to energy transition. Oil and gas products and byproducts are ubiquitous across the globe, and it is too simple to blame the industry for their pervasiveness in all facets of life. Yet, this universal dependency must be reduced. Additionally, the oil and gas industry creates greenhouse gas emissions across their process lifecycles from extraction and refinement through distribution and consumption.

As a result, the oil & gas industry is under more pressure than any other to reduce emissions and implement net-zero goals by divesting and mothballing high-emissions business. To do so, industry players must aggressively learn how to connect operations to improve sustainability, diversifying their energy services portfolio, and demonstrating more overall corporate responsibility in reducing the impact of climate change. This pressure has magnified as investment firms have begun insisting capital allocation be tied to formal sustainability plans and measurement.

The oil and gas industry is challenged to accomplish the following:

• Significantly reduce direct carbon emissions of current operations related to the extraction and processing of oil and gas.

• Diversify energy portfolio to include low-carbon solutions. This initiative is also related to the potential growth opportunity of energy services companies, specifically by potentially monetizing renewable energy, carbon capture, hydrogen and biofuels. and electric vehicles (EV) markets.

• Support the reduction of oil and gas necessary in consumer products, such as single-use plastics, furniture, and clothing.

Manufacturing Sustainability Must Be Unequi-vocally Quantifiable

Discrete, hybrid, and process manufacturing companies are under serious external pressure from investors, communities, and politicians to improve sustainability. Increasingly, manufacturers are being required to quantitatively demonstrate sustainability improvements. Organizing their people, culture, systems, processes, resources, and ecosystems to do so might be their most daunting challenge to date. Certainly, it will incorporate most, if not all, digital transformation initiatives already underway or on the drawing board.

Some sustainability strategies will require what seems obvious on the surface—reducing emissions and energy usage, reducing scrap and waste, employing circular economy business practices, and lowering the carbon footprint of products (e.g., chemicals). However, it will require immense and transformative change to get these things done. Additionally, there are volumes of yet to be defined work needed beyond these efforts, and that is where the major challenges lie.

One of the most existential difficulties for manufacturers is simply defining what sustainability means relative to their vast, complex ecosystems (from sourcing through consumption), and proving quantifiably that any efforts undertaken support that definition. Given how ingrained manufacturing is in the very fabric of our global economy, it is simply overwhelming for many manufacturers to understand where their responsibility begins and ends.

Technologies to Consider

The number of technologies, both entrenched and emerging, that can contribute to a business-wide sustainability effort are vast. To be sure, there are some well-known regulatory-driven tracking and reporting systems that have traditionally played a role, such as energy and building management systems, geospatial information systems (GIS), manufacturing execution systems (MES), and environmental, health, safety compliance (EHS) systems. They likely will continue to do so, although for the last one it is still uncertain whether it will evolve to support modern notions on sustainability, fill a more niche role, or eventually be replaced as antiquated by broader ESG platforms and set of accompanying applications.

Additionally, many technologies that support digital transformation can, by their very nature, address sustainability issues and use cases. Machine learning and other forms of artificial intelligence (AI) are good, straightforward examples. Solutions could be provided through one or more of the following:

• Combined hardware and software

• Standalone delivery or as part of a system or application

• Ad hoc creation using microservices

• Professional services toolkit

Regardless of the technologies applied to sustainability performance, asset-intensive industries will still face major challenges proving quantifiable net value. For example, the most obvious starting point is the optimization of assets, a seemingly obvious improvement in energy efficiency and emissions reduction. However, within a siloed view of sustainability, the optimization of those assets might contribute negligibly in the face of aggressive reduction targets. This is particularly true for aged assets in service that were never designed to meet the sustainability requirements of today. To be sure, their performance should be optimized, but it may need to be managed within the performance criteria of a larger strategic goal.

Recommendations and Plan of Action for Companies

Considering what is at stake, ARC recommends the following actions for organizations to plan and implement sustainability and ESG strategies:

• Proactively work with your customers: Many companies are waiting for pressure from their customers as to how operations and performance need to evolve and be measured. Don’t wait. Engage your customer base to determine how they are and will be held accountable. Begin to work that into your strategies.

• Adopt a framework: Once you have identified the performance indicators critical to your customers, identify a working framework that is specific and quantifiable. Use this framework to develop your strategies.

• Understand progress will be iterative: People are just beginning to understand both the vast scope and complexity of change required to address climate change. Like transformation, it will be iterative, and innovation will occur along the way. Demonstrations of good faith action and improvement will be necessary as your efforts evolve.

• Address the obvious: Optimized assets reduce emissions and energy inefficiency. As part of digital transformation, your organization should already be working toward asset optimization, so continue to push these efforts. However, understand that this optimization cannot be a siloed approach to sustainability, as it must fold into a higher-level sustainability strategy.

• Support and require transparency: To quantify your company’s sustainability performance, you know where your responsibility begins and ends. This will require both upstream and downstream data and performance transparency.

• Don’t overlook the people aspect: As with all change, the people component is the most difficult. For sustainability, understand you will need many new skills, from economists to technologists, and some that have yet to be created. Additionally, sustainability must become a cultural norm with the workforce. Apply the same diligence as you would to operational safety.

m