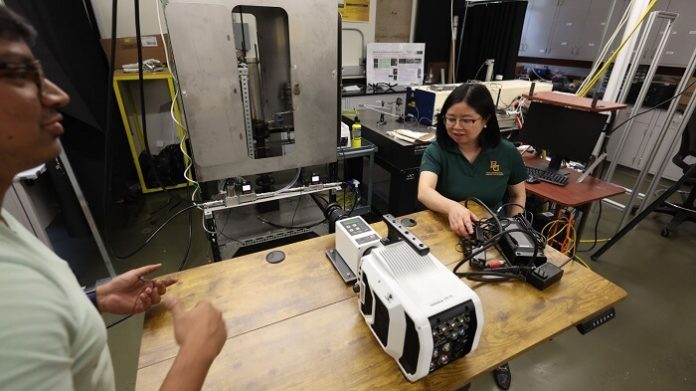

In a groundbreaking study, researchers from Baylor University’s Cornerstone Atomization and Combustion Lab (CAC) have developed an innovative approach for efficiently burning biofuels. Utilizing a revolutionary Swirl Burst (SB) injector, the team demonstrated the capability to combust glycerol/methanol blends with near-zero emissions, marking a significant advancement in sustainable energy solutions.

This research holds promise for both academic exploration and industrial application, potentially setting new benchmarks in the biofuel sector. “This study illustrates how viscous bio-waste can be converted into clean energy using our combustion technology,” said Dr. Lulan Jiang, assistant professor of mechanical engineering and principal investigator of the CAC Lab.

Transformative Potential for the Biofuel Industry

Glycerol, a byproduct of biodiesel production, is typically challenging to burn due to its high viscosity, which limits its utilization despite its moderate energy density. Traditional injectors often struggle with this viscous substance, but the SB injector’s unique design allows for efficient combustion without the need for costly fuel preheating or processing.

The SB injector achieves a complete and clean burn by producing fine droplets, which significantly reduces harmful emissions, including carbon monoxide (CO) and nitrogen oxides (NOx). Jiang emphasized that this novel technology enables biodiesel producers to transform glycerol waste into a valuable fuel source, fostering a circular economy and decreasing the carbon footprint associated with energy generation. Additionally, the injector’s versatility permits combustion of various glycerol/methanol ratios without requiring hardware modifications, making it ideal for power plants that must comply with stringent emissions standards.

“By converting waste glycerol into cost-effective renewable energy, we promote energy resilience and equity for economically disadvantaged communities in an era of climate change,” Jiang noted.

Testing and Results

As reported by press release, the research team examined three distinct fuel blends—50/50, 60/40, and 70/30 glycerol to methanol ratios—evaluating their performance at multiple atomizing air-to-liquid mass ratios (ALR). All blends exhibited over 90% combustion efficiency, with the 50/50 blend achieving complete combustion and near-zero emissions of CO and NOx, even in non-preheated and uninsulated setups. This represents a significant improvement over traditional air-blast or pressure-swirl injectors, which often produce higher emissions when dealing with high-viscosity fuels.

“The SB injector’s high viscosity tolerance and fuel flexibility indicate that not only waste glycerol but also viscous biodiesel feedstocks and other waste-based bio-oils can be directly utilized for energy generation without additional processing. This capability could significantly reduce biofuel costs and encourage broader adoption,” Jiang explained.