Clariant, a sustainability-focused specialty chemicals company, has successfully introduced its new Plus series syngas catalysts.

Over the last five years, the company has upgraded its syngas catalyst portfolio, launching the ReforMax LDP Plus, ShiftMax 217 Plus, and AmoMax 10 Plus.

Clariant Enhances Syngas Catalyst to build upon the success of their predecessors, offering drop-in solutions designed to improve plant economics and reduce carbon emissions.

Commercial use has already demonstrated highly favorable results, confirming their effectiveness.

Step Toward Decarbonization

Georg Anfang, Vice President of Syngas and Fuels at Clariant Catalysts, emphasized the importance of every action in reducing CO2 emissions.

Anfang said, “The transition to decarbonize the chemical and energy industries is lengthy, and every ton of CO2 savings counts to reach our ultimate goal of net zero. Our syngas Plus catalysts are designed to improve efficiency and sustainability while enabling the deployment of new low-carbon applications like hydrogen and ammonia production,”.

The Plus series represents Clariant’s commitment to advancing the global shift toward sustainable chemicals and fuels.

ReforMax LDP Plus

The ReforMax LDP Plus series, a next-generation catalyst for steam reforming, is used in the production of hydrogen, ammonia, and methanol.

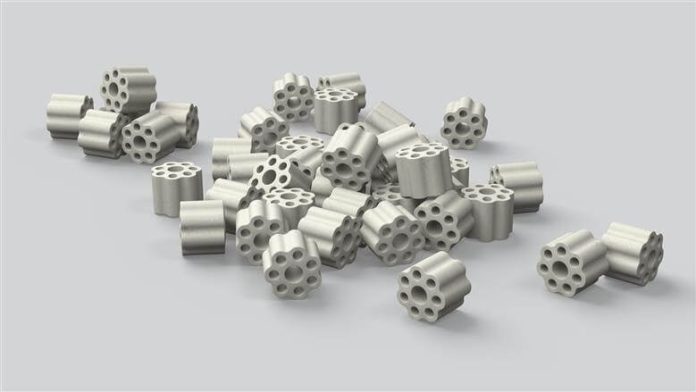

The catalysts feature a unique flower-like 8-hole shape, which reduces pressure drop in reactors by up to 20% compared to previous catalyst shapes.

This innovation improves heat transfer, saves energy, and extends the service life of reformer tubes.

ReforMax 330 LDP Plus was first installed six years ago in a European ammonia plant with a capacity of 1650 mtpd. Since then, it has demonstrated a 20% lower pressure drop than its predecessor.

After six years of operation, the catalyst has stabilized, and thermal imaging of tube wall temperatures shows excellent heat distribution throughout the furnace.

To date, more than 40 production plants around the world have benefitted from the increased productivity enabled by ReforMax LDP Plus.

ShiftMax 217 Plus

The ShiftMax 217 Plus, a low-temperature water gas shift catalyst, offers significantly improved selectivity while maintaining the high activity and stability of its predecessor.

This enhancement reduces methanol formation, a harmful by-product and regulated volatile organic compound (VOC).

As a result, ammonia producers experience higher yields with lower energy consumption.

For example, a European ammonia plant that installed ShiftMax 217 Plus two years ago has seen methanol formation decrease by more than 50%.

This reduction ensures compliance with VOC limits and translates into significant cost savings over the catalyst’s six-year expected lifetime.

AmoMax 10 Plus

The AmoMax 10 Plus is Clariant’s new wustite catalyst for ammonia synthesis, building on the proven performance of the AmoMax 10.

With an improved promoter set, this catalyst offers higher activity and greater robustness against catalyst poisons, as well as faster startups.

Clariant Enhances Syngas Catalyst to enable higher per-pass conversion and lower loop pressure, improving both ammonia production and energy efficiency.

At a European ammonia plant since 2021, the AmoMax 10 Plus has delivered a 24% increase in relative activity compared to the previous generation, enhancing overall plant efficiency.

Comprehensive Solutions

Together, the ReforMax LDP Plus, ShiftMax 217 Plus, and AmoMax 10 Plus catalysts offer a comprehensive solution to improve performance and sustainability across the syngas value chain—spanning reforming, water gas shift, and synthesis.

As per the press release, with rising energy costs and the urgent need to reduce carbon emissions, each improvement in plant operation is a valuable contribution to both the bottom line and the environment.