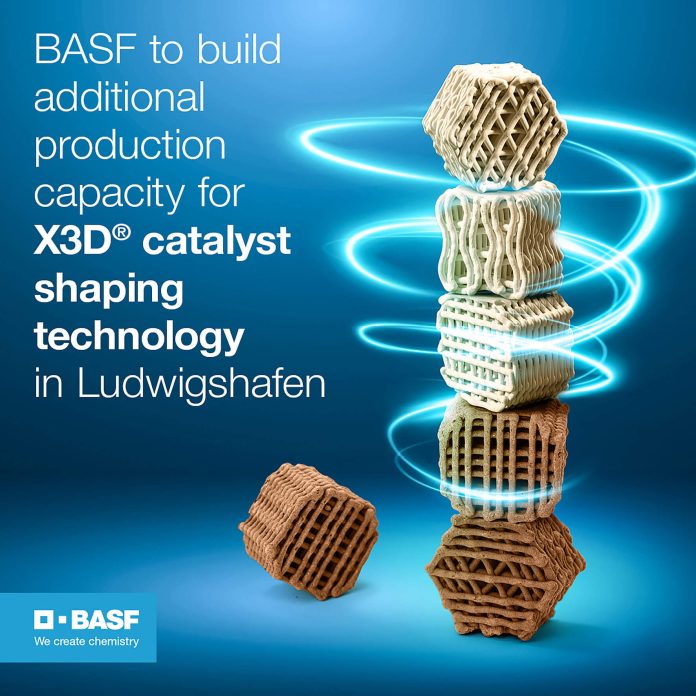

BASF announced plans to invest in additional production capacity for its X3D® technology, a groundbreaking additive manufacturing technology for catalysts.

The new facility, set to be operational in 2026, will enable BASF to produce catalysts on an industrial scale, significantly advancing its ability to meet growing customer demand.

Transforming Catalyst Design and Performance

X3D technology is a significant leap forward in the design and production of catalysts. Catalysts made using this technology are not only mechanically robust but also feature an innovative open structure.

This design dramatically reduces the pressure drop across reactors while increasing the surface area, which enhances catalyst performance.

As a result, customers can expect improved reactor output, higher product quality, and reduced energy consumption, all of which contribute to achieving their green transformation goals.

Versatility and Customization

One of the standout advantages of X3D technology is its versatility. It can be applied to a wide range of catalytic materials. It includes both precious and non-precious metal catalysts as well as various carriers.

This flexibility allows BASF Investment to tailor catalysts to specific customer needs by adjusting parameters such as infill patterns, fiber diameters, and orientations, ensuring that every solution is optimized for maximum efficiency.

Innovation and Sustainability

BASF remains committed to leading innovation in the chemical catalysts industry.

Detlef Ruff, Senior Vice President of Process Catalysts at BASF stated, “X3D represents a step-change advancement in catalyst production. We are proud to provide our customers with new opportunities to enhance performance while reducing their carbon footprint”.

The Potential

BASF has already seen significant success with X3D catalysts in commercial plants over several years, achieving impressive results.

Jens Perregaard, Vice President of Custom Catalysts and Innovation at BASF highlighted, “X3D is poised to shape the future of both green and traditional value chains by delivering unparalleled efficiency and faster speed-to-market”.

As per the press release, with this new investment, BASF will continue to position it as a leader in sustainable catalyst solutions, driving both innovation and performance for its customers worldwide.