AGC Inc. (Headquarters: Tokyo; President: Yoshinori Hirai), a global leader in glass, chemicals, and advanced materials, has signed a joint research agreement with Canada-based climate tech startup CERT Systems Inc. (CERT). Together, they will explore the production of ethylene from CO2 using cutting-edge electrolysis technology. This collaboration of AGC and CERT marks a step toward introducing CO2 capture and utilization (CCU) technology into AGC’s processes, aiming to replace conventional ethylene—used in products like polyvinyl chloride and fluoropolymer resin with a more sustainable, CO2-derived alternative.

Advancing Carbon Neutrality with CCU Technology

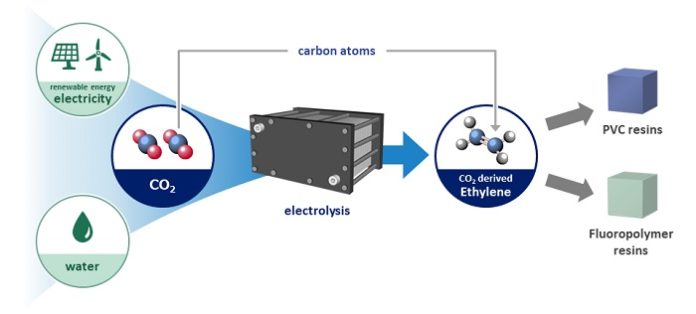

As the world focuses on carbon neutrality goals for 2050, CCU technology has emerged as a promising solution. Among the three primary methods for producing CO2-derived ethylene, two are hydrogen-based reactions and photosynthesis-based reactions. The third method, electrolysis reactions, stands out. Its use of renewable energy-derived electricity, water, and CO2 makes it a globally favored approach for sustainable production.

Leveraging CERT’s Groundbreaking Expertise

The joint research will build on CERT’s landmark achievement in 2020, where it became the first in the world to produce ethylene from industrial CO2 emissions through electrolysis. CERT and AGC will collaborate to develop this technology further, working toward the practical implementation of CO2 electrolysis plants. The AGC Group will utilize its manufacturing bases to validate the process and evaluate its feasibility.

Aligning with AGC’s Sustainability Goals

As per the press release, this initiative aligns with AGC’s medium-term management plan, AGC plus-2026, which prioritizes sustainability management. AGC has committed to achieving “carbon net zero” by 2050, and this joint research represents a key step in meeting that target. By focusing on CO2 electrolysis, AGC aims to revolutionize its production processes while contributing to global sustainability efforts.

AGC and CERT are collaborating to pave the way for innovative solutions. These solutions address climate challenges and promote sustainable industrial practices.