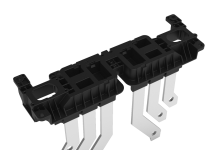

BASF has unveiled a flame-retardant (FR) grade of Ultramid® T6000 polyphthalamide (PPA), now utilized in terminal block applications for electric vehicles (EVs).

The advanced material replaces non-FR alternatives, significantly improving safety for inverters and motor systems in EVs.

Innovative Material with Superior Properties

Ultramid T6000 bridges the performance gap between traditional PA66 and PA6T.

It offers outstanding mechanical and dielectric properties, particularly under humid conditions and high temperatures.

Additionally, it ensures easy processing and reduces tool corrosion, making it ideal for complex automotive applications.

The material’s extensive range of pre-color options, including vibrant shades, provides design flexibility without compromising performance.

Commitment to EV Safety Standards

“As safety becomes increasingly vital in the design and material selection for metal components in EVs, such as wiring terminals and busbars, BASF is committed to developing innovative solutions for the EV industry,” stated Eng Guan Soh, Vice President, Business Management Engineering Plastics, Performance Materials Asia Pacific at BASF.

Soh added, “Our goal is not only to meet today’s design needs but also to equip our customers with tools for developing cutting-edge technologies that address future technical requirements and safety standards”.

Exceptional Performance Under Extreme Conditions

The FR grade of Ultramid T6000 is engineered specifically for EV applications, delivering high strength and durability for terminal block use.

It withstands extreme thermal shock, ranging from -40°C to 150°C, for up to 1,000 cycles.

Moreover, it ensures excellent electrical isolation for terminal blocks and high-voltage busbars, making it an ideal choice for vehicles with 800V platforms.

Non-Halogenated Flame Retardant for Enhanced Safety

A notable feature of Ultramid T6000 is its non-halogenated flame retardant, which minimizes metal corrosion risks.

This meets stringent safety standards and provides superior protection for vehicle occupants in fire-related incidents.

Facilitating Complex and Efficient Designs

Ultramid T6000 also boasts remarkable strength, stiffness, and dimensional stability, enabling intricate designs that endure automotive assembly challenges.

Its ability to integrate multiple functions into single components simplifies assembly processes and enhances space efficiency in EVs.

As per the press release, with these advancements, BASF continues to lead innovation in materials designed to meet the evolving demands of the electric vehicle industry.