Abstract

The global bio-based polymer industry is experiencing remarkable growth, with production capacity expected to increase significantly over the next five years. Driven by favorable policy frameworks, growing investments in regions such as China, Europe, the Middle East, and the US are boosting capacity expansion, particularly for polylactic acid (PLA) and other bio-based materials. This article explores current trends, capacity developments, and the policy initiatives shaping the future of bio-based polymers, highlighting their rising role in sustainable and circular economies.

Introduction

As the world shifts towards sustainable and renewable materials, the bio-based polymer industry is emerging as a critical player in the global effort to reduce reliance on fossil-based plastics. With a projected compound annual growth rate (CAGR) of 13-18% through 2029, bio-based polymers are outpacing their fossil-based counterparts in production growth.

This surge is supported by substantial investments in capacity expansions across key regions and the introduction of new policy frameworks, such as the European Union’s Packaging and Packaging Waste Regulation (PPWR). In this article, we delve into the latest developments in bio-based polymer capacity, explore key projects in major regions, and analyze how evolving policy landscapes are driving innovation and demand in the industry.

As the New Year begins, let’s take a closer look at the current state of bio-based polymers. We look at the rapidly growing production capacity, the major investments currently underway in China, Europe and the Middle East, and the new political conditions in Europe that are driving demand for biodegradable polymers. But first things first.

Impressive Growth

Firstly, global capacity for bio-based polymers will grow strongly over the next five years, much faster than for fossil-based polymers. For the 14 bio-based polymers presentedat the European Bioplastics Conference (EBC December 2024 in Berlin), the expected compound annual growth rate (CAGR) between 2024 and 2029 is an impressive 18% – total capacity will increase to 5.7 million tonnes in 2029, with PLA accounting for the largest share.

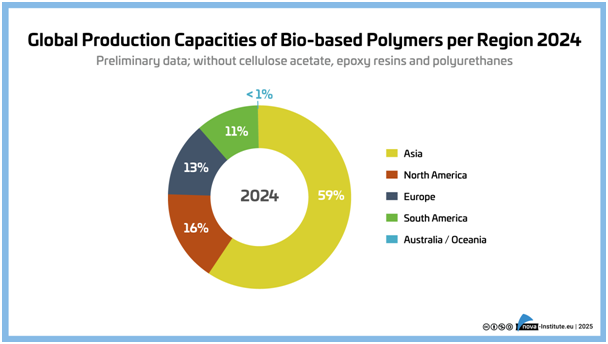

The data was collected by the international nova expert group on bio-based polymers. Taking into account all 17 commercially available bio-based polymers[1], the CAGR between 2024 and 2029 is 13%, compared to 2-3% for fossil-based polymers. This would mean that the capacity share of bio-based polymers in the total polymer market will increase from 1% today to around 1.5% in the coming years.

[1] For more details please see: Bio-based Building Blocks and Polymers – Global Capacities, Production and Trends 2023–2028 (https://renewable-carbon.eu/publications/product/bio-based-building-blocks-and-polymers-global-capacities-production-and-trends-2023-2028-short-version/)

The low utilisation rate of some capacities, especially for PLA capacities in China, was also shown and discussed. This has already been shown in the report “Bio-based and Biodegradable Plastics Industries in China” published by the nova-Institute in May 2024[2].

China’s bio-based polymer industry is experiencing rapid growth despite being in its early stages, largely propelled by policy incentives. Projections suggest that the industry will expand substantially, reaching 2.53 million tonnes by 2026, up from 765,000 tonnes in 2023, representing a notable CAGR of approximately 49%.

[2]Bio-based and Biodegradable Plastics Industries in China” published by the nova-Institute in May 2024 (https://renewable-carbon.eu/publications/product/bio-based-and-biodegradable-plastics-industries-in-china-short-version-pdf/)

Investments and Production

Second, investments in new capacity will take place in China, Europe, the Middle East, and the US. NatureWorks (US) is the current major producer of lactic acid (LA) and polylactic acid (PLA).

The installed capacities of 198,000 tonnes/year for LA and 165,000 tonnes/year for PLA in the United States will be increased in 2025 with new installations in Thailand. Adding a total of 175,000 tonnes/year Asian production capacity to NatureWorks North American capacity.

Belgium’s Futerro will become the world’s second largest producer of LA and PLA. Projects in China, together with BBCA Biochemical, have realised 30,000 tonnes/year of PLA capacity, now expanding to 150,000 tonnes/year. The next Futerro plant will be located in Normandy, France.

With an estimated total investment of € 500 million, it will be Europe’s first fully integrated, circular and sustainable biorefinery. With an annual production capacity of 125,000 tonnes of LA and 75,000 tonnes of PLA combined with its recycling, this project is a world first in the field of bio-based polymers.

Emirates Biotech, a newcomer to PLA production, announced in December 2024 specific details of its planned PLA project in the United Arab Emirates. The 160,000 tonnes/year biopolymer plant will be the first PLA production facility in the Middle East. Emirates Biotechselected Sulzer as the technology provider for the plant, which will be built in two phases, each with an annual capacity of 80,000 tonnes.

Construction of the first PLA plant is scheduled to start in 2026 and the plant is expected to be operational in early 2028. The plant will use lactic acid as its feedstock. Emirates Biotech’s new CEO, Marc Verbruggen, formerly of NatureWorks, presented at EBC2024 several drivers for PLA growth in the Middle East, including increasing demand for sustainable packaging, favourable regulatory support and policies, and innovative applications creating new markets for PLA.

The US Plastics Industry Association showed at EBC2024 that in 2022, US bio-based polymer production, including mass balance-derived polymers, accounted for 0.6% of the country’s total polymer production. The US will be the world’s second-largest producer of bio-based polymers, accounting for 19% of global production in that year. By 2028, US bio-based polymer production capacity is projected to increase by 17%.

Industrial Compostability

Thirdly, investment in bio-based polymer capacities is mainly driven by policy frameworks that create demand. The most recent example is the European Union’s Packaging and Packaging Waste Regulation (PPWR). On 16 December the European Council formally adopted the PPWR. The new rules aim to reduce the generation of packaging waste by setting binding recycling targets, restricting certain types of single-use packaging and requiring economic operators to minimise the packaging used.

For the first time, there is an obligation for industrial compostability for a few applications: “permeable tea, coffee or other beverage bag, or soft after-use system single-serve unit that contains tea, coffee or another beverage, and which is intended to be used and disposed of together with the product; and sticky labels affixed to fruit and vegetables”.

Furthermore, Member States may still decide for themselves whether to make other applications compostable (provided that sufficient infrastructure is available): “non-permeable tea, coffee or other beverage system single-serve unit intended for use in a machine and which is used and disposed of together with the product; composed of material other than metal, very lightweight plastic carrier bags and lightweight plastic carrier bags”.The whole regulation will apply from 36 months after its entry into force. So from January 2028.

The impact of this new regulation was already evident at the conference when two companies – TotalEnergies Corbion (FR/NL) and Sinclair International (UK) – presented at EBC2024 sticky labels for fruit and vegetables made from industrial compostable plastics, glue and inks. Other companies will soon follow, demonstrating the dynamism and speed with which the industry is responding to new sustainable demand created by policy.

Another important step is to create demand for soil-biodegradable products: Soil-biodegradable mulch films, coatings and water-retention polymers are included in the European Union’s Fertilising Products Regulation (FPR). The newly defined biodegradability criteria are strict but scientifically based and will fully demonstrate that certified soil-biodegradable mulch films are environmentally safe and can even contribute to soil health and fertility as a ‘soil improver’.

These soil-biodegradable products can carry the CE mark – from 20 November 2024 for biodegradable mulch films and from 17 October 2028 for coatings and water retention polymers – which means that they have been additionally assessed to meet the high safety, health and environmental protection requirements of the European Union and can be traded without restrictions in the extended single market of the European Economic Area (EEA). “The inclusion paves the way for further investment, innovation and research in this field, which is closely linked to a circular bio-economy,” says Hasso von Pogrell, Managing Director of European Bioplastics.

The next major event on renewable polymers (full second day) and biodegradation (third day) will take place in Siegburg, Germany on 22-24 September 2025 with an expected 500 attendees: Renewable Materials Conference. Don’t miss the early bird registration: www.renewable-materials.eu. Further information:

– nova-Institute: www.nova-institute.eu

– News, events, publications, graphics and business directory: www.renewable-carbon.eu