Japanese technology leader Asahi Kasei has been honoured with the prestigious Okochi Memorial Prize, a recognition of exceptional contributions to production engineering and advanced manufacturing methods in Japan. The award celebrates the company’s breakthrough in pharmaceutical formulation with the development of Ceolus™ UF grade microcrystalline cellulose (MCC)—a solution addressing longstanding challenges in tablet manufacturing.

Solving Tablet Formulation Challenges with Ceolus™ UF

MCC Ceolus™ is made from natural pulp and is widely used as an excipient in pharmaceutical and nutritional supplements. As a tablet binder, its primary role is to provide compactibility and flowability—two essential properties for consistent tablet production. Traditionally, balancing these qualities has been a persistent obstacle for drug manufacturers.

Asahi Kasei’s Ceolus™ UF grade overcomes this limitation with an innovative porous particle design that enables both high compactibility and superior flowability. This unique structure ensures:

- Strong tablet hardness, preventing issues such as capping and chipping

- Efficient powder filling, boosting production throughput

- Uniform API distribution, even in low-dose formulations

These advancements not only enhance manufacturing efficiency but also enable the creation of smaller, more patient-friendly tablets, supporting the development of complex dosage forms.

Industry Recognition and Global Impact

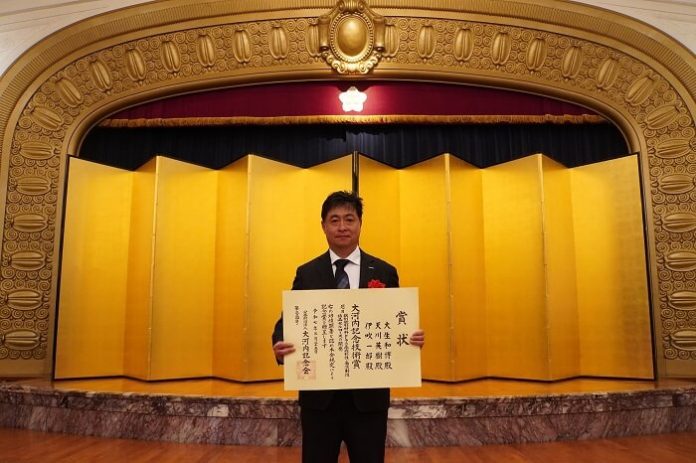

The Okochi Memorial Foundation acknowledged this contribution as a major advancement in pharmaceutical production technology.

“We are very proud to achieve this award,” said Hideyuki Kimura, Senior General Manager, Asahi Kasei Healthcare Materials Division. “It highlights Ceolus™’s pivotal role in the pharmaceutical industry and reinforces our commitment to solving complex development challenges. We continue to innovate for better patient outcomes and improved user experience,” Kimura added.

Supporting Nitrosamine Risk Reduction

Alongside its formulation benefits, Ceolus™ also plays a crucial role in enhancing pharmaceutical safety. Nitrosamine impurities, linked to carcinogenic risks, have raised significant safety concerns since 2018. In response, global regulatory bodies such as the EMA and FDA have pushed for stricter control measures.

To address this, Asahi Kasei now offers MCC grades, including Ceolus™, with ultra-low nitrite levels (≤0.1 μg/g or ppm). Reducing nitrite content is key to limiting nitrosamine formation, a byproduct of nitrosation reactions during drug production.

Asahi Kasei backs each Ceolus™ batch with verified testing and Certificates of Analysis. This support helps pharmaceutical manufacturers meet stringent regulatory standards and safeguard patient health.

A Commitment to Innovation and Patient-Centric Solutions

From solving tablet formulation issues to advancing impurity control, Asahi Kasei continues to deliver technologies that enhance manufacturing reliability, regulatory compliance, and end-user experience. As per the press release, the Okochi Memorial Prize stands as a testament to the company’s leadership in pharmaceutical innovation and responsible production.