Introduction

During the lockdowns last year in their various incarnations, whether first covid wave or second wave and its lifting thereafter, partial or otherwise, too many accidents have taken place in the chemical and allied industries, bringing into question the very existence of chemical plants and their operation. That number is around 100. What went wrong? The word ‘Chemical’ is taboo for the public. Chemicals can be very simple molecules requiring only a few steps for synthesis and plant operations or they could be complex structures needing many steps leading to waste of materials and energy at each stage. Hazard is present at each stage. Even a slight variation in the geometrical, conformational or stereo properties can make a chemical toxic or non-toxic. Can dyes, surfactants and other intermediates be made safe through design or redesign looking at the sectors where they are used? Remember, the chemical industry is very diverse, producing thousands of substances which are used by other industries and that are present in countless consumer products. No man-made product can be made without the use of chemicals. The chemical industry makes products with many beneficial uses, but they can also have negative impacts on human health and the environment. By their nature, the manufacture, storage, and transport of chemicals have the potential for accidents to happen. Chemicals can be toxic, and they may react, often violently and explosively during transport, storage, or reaction. The impacts of chemical accidents can be deadly. Public faith has eroded due to the negative coverage in media, notwithstanding the fact that chemical and allied industries including refineries, petrochemicals, pharmaceuticals, polymers, agrochemicals, intermediates, etc. are essential and an important segment of the economy. They are not optional; they will contribute very significantly to hon’ble P.M.’s dream of USD 5 trillion economy, the China factor notwithstanding.

Defining Accidents

So, what is an accident or incident? To describe health and safety in workplaces, incidents and accidents are extremely common and often these two terms are interchanged. In most cases they indicate the level of destruction or damage that results from a workplace occurrence. Accident is an unexpected event which results in serious injury or illness of an employee and may also result in property damage. A “near-miss”covers a narrowly averted accident whereas Incident means an instance of something happening, an unexpected event or occurrence that doesn’t result in serious injury or illness but may result in property damage. All of them are associated with unexpectedness. All industries face all these realities.

Accidents are part and parcel of modern civilization, if we step out of our homes, in our workplaces, no matter what job we do or how we travel, something unexpected can happen. The frequency and severity of such accidents are the real causes to worry about. So, what lessons has the industry learnt to avoid accidents? Can the plants be operated safely? Can the Chemical Industry be as safe as the Nuclear Industry or beyond? As an educator and researcher, I would like the readers to ponder on what follows.

Accidents are part and parcel of modern civilization, if we step out of our homes, in our workplaces, no matter what job we do or how we travel, something unexpected can happen. The frequency and severity of such accidents are the real causes to worry about. So, what lessons has the industry learnt to avoid accidents? Can the plants be operated safely? Can the Chemical Industry be as safe as the Nuclear Industry or beyond? As an educator and researcher, I would like the readers to ponder on what follows.

Risk in Polymerization

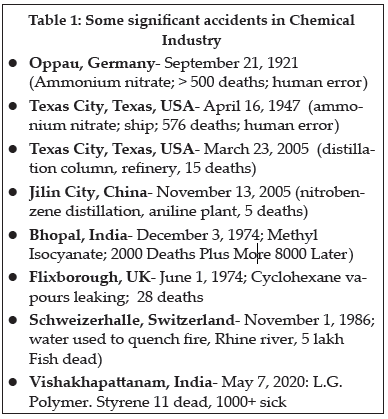

Accidents can happen due to many factors and the most talked about term in the industry is ‘Runaway’ situation: uncontrolled temperature rise leading to untoward consequence as has been the case with many major accidents over the years. (Table 1). The Vizag accident on May 7, 2020, due to styrene leak in the vapour form (not the gas as the ‘breaking news- TV channels’ said) brought to my attention, how polymerizations could lead to runaway: initiation, propagation and termination. What triggers an incident, what propagates it and how to terminate it. The objective of Loss Prevention is: Minimize the probability that the accident begins or maximize the probability that the sequence terminates benignly if it does start, or minimize the consequence if it terminates malignantly.

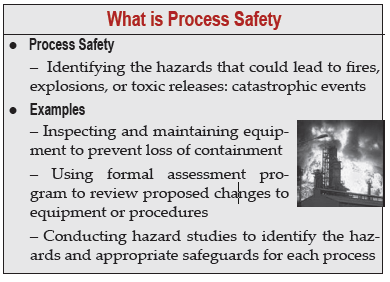

You might have studied it in polymerizations: initiation, propagation, and termination as part of reaction mechanism. You will be surprised to know that polymerizations lead the cases of accidents in industry, followed by nitration, sulfonation, hydrolysis, salt formation, hydrolysis, halogenation, Friedel Crafts alkylation, amination, diazotization, oxidation, esterification and hydrogenation, which normally would be thought to be more dangerous! This has been given by the great author Trevor Kletz, with whom I had the honour of sharing the office for a year in the Loughborough University (of Technology, then) during 1980-81 when I was a young Leverhulme Fellow. He worked for the ICI, UK, now defunct. He is used to write his books and would discuss it with Professor Frank Lees and Dr Pete Andow from the same University, who are equally well known on process safety and risk management. Frank Lees’ books on Loss Prevention are legendary. So what is process Safety.

You might have studied it in polymerizations: initiation, propagation, and termination as part of reaction mechanism. You will be surprised to know that polymerizations lead the cases of accidents in industry, followed by nitration, sulfonation, hydrolysis, salt formation, hydrolysis, halogenation, Friedel Crafts alkylation, amination, diazotization, oxidation, esterification and hydrogenation, which normally would be thought to be more dangerous! This has been given by the great author Trevor Kletz, with whom I had the honour of sharing the office for a year in the Loughborough University (of Technology, then) during 1980-81 when I was a young Leverhulme Fellow. He worked for the ICI, UK, now defunct. He is used to write his books and would discuss it with Professor Frank Lees and Dr Pete Andow from the same University, who are equally well known on process safety and risk management. Frank Lees’ books on Loss Prevention are legendary. So what is process Safety.

What is System Safety Process?

What is System Safety Process?

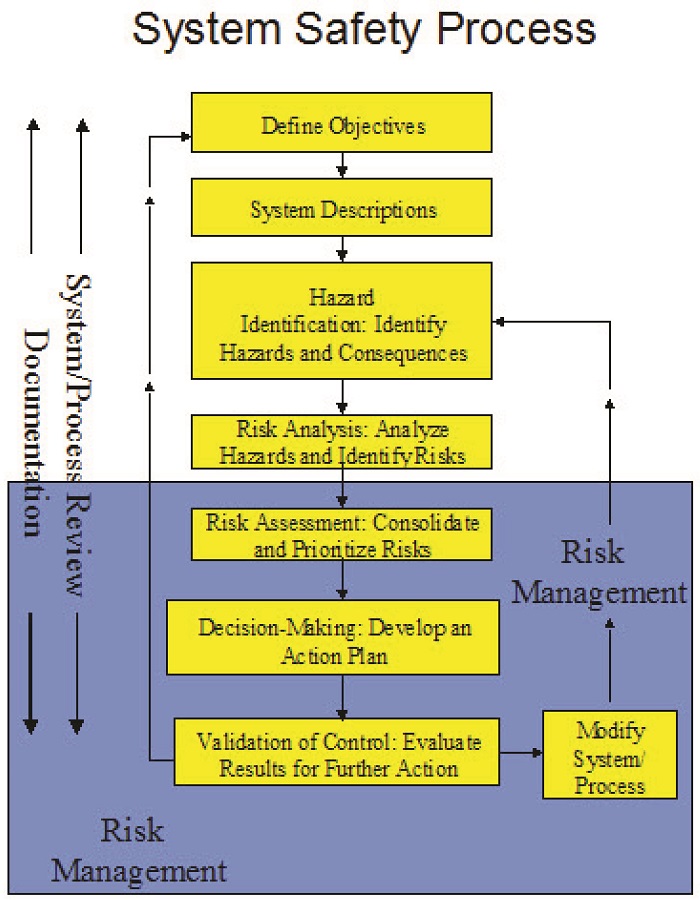

A systematic approach to process improvement requires proactively searching for opportunities to improve the process at every step, not simply identifying deficiencies after an undesired event. The steps in the system safety process are depicted graphically in Fig 1.

So, if you are in the business of manufacturing: “Expect the unexpected” and anticipate that accidents can happen even in the most ‘benign’ plant due to human error. Most accidents are due to human error. Some of the pertinent questions to be asked are:

• The specific type of incident/accident was not anticipated by the design engineers or system while designing or operating the plant, and for which, of course, there was no emergency plan for prevention and containment with no loss or minimum loss of life, plant and/or business. Loss of prestige of the manufacturer is disastrous for business.

• Was the Incident/Accident either due to failure of equipment or human error?

• Human error or overfamiliarity is the majority cause of accidents (>95%)

• What was the inherent process hazard analyzed and steps were taken into account?

• Was accident due to less attention to safety to save money or due to short-cut in the SOP?

• Were natural causes due to flood, earthquake, tsunami, etc. considered, due to the geography?

• What about the molecular group or hazardous properties of all chemicals and materials on the site, and not just in process? Were all these likely causes of accident considered while designing or operating the plant?

• What about the hazard and risk due to the neighbouring plant and processes in the same zone?

• Was process simulation for hazard identification, analysis and risk management done during start-up or commissioning or actual operation?

• Who trains the new personnel on past accidents in the same plant? Is it hidden from new recruitment causing more danger to both parties?

Risk can emanate from anywhere

Many accidents are started by the plants in the vicinity or processes of which no knowledge is shared due to trade secrecy. The adage should be ‘Keep an eye on your neighour.’ Recent events in Indian industry are a testimony to this fact. In Chemical Process Industry everything, including the Material, Machine or Man, has a potential to cause incident or accident, unfortunately in that order. If it is a chemical in process or storage or transported as gas, liquid, or solid form, it has a potential to cause disastrous consequence. The chemical on site which is not part of the process can cause severe damage if its properties are not considered. The management must know all their chemicals, solvents and personnel who are running the plants and deal with them daily. As the proverb goes familiarity can breed contempt. Training of personnel from time to time, including the security at the site who have to deal with the emergency, is very crucial.

Risk is typically defined as ‘hazard x exposure’ or ‘consequence x probability’. Making the probability zero or exposure zero would be the most ideal solution. The normal definition of hazard is inadequate when we consider accidents which have taken place over the years. Hazard is not restricted to physical hazards such as explosiveness, flammability, and corrodibility, but certainly also includes acute and chronic toxicity, carcinogenicity, and ecological toxicity. Hazard must include global threats such as global warming, stratospheric ozone depletion, resource depletion and bioaccumulation, and persistent chemicals. Intrinsically hazardous properties of chemicals constitute those issues that can be addressed through the proper design or redesign of chemistry and chemicals. So much so we can define ‘Safer Chemicals’ to reduce pollution and risk at source. The advances in molecular toxicology and the relationship between chemical structure and important property exploited for industrial application are the basic tools. Synthesis using Catalysis, Renewable Resources, Atom Economy and Solventless Conditions will be the hallmark of plants in the future.

Inherently Safe

In fact, industry must move from Current Chemicals to Inherently Safer Chemicals to Inherently Safer Plants by adopting the following strategies:

• Designing a new molecule that is safe

• Redesigning an existing molecule to make it safe

• Increasing user safety.

• Increasing transportation safety by training the drivers and attendants on duty. Not to extend the duty more than 3 hours at stretch and change the driver or take rest for some time. The same driver should not have more than 7 hours duty in a day.

• But how do we manufacture a given chemical, inherently safe or otherwise?

• What is the limit of our “smartness” in tailor-making a molecule or product?

• What about the currently manufactured Chemicals & the plants?

If the industries develop, design, operate and control a chemical process such that the consequence is reduced because of different chemistry, chemicals, conditions or simplicity, wouldn’t the safety of the plant be improved? Is this not better than layers of protection?

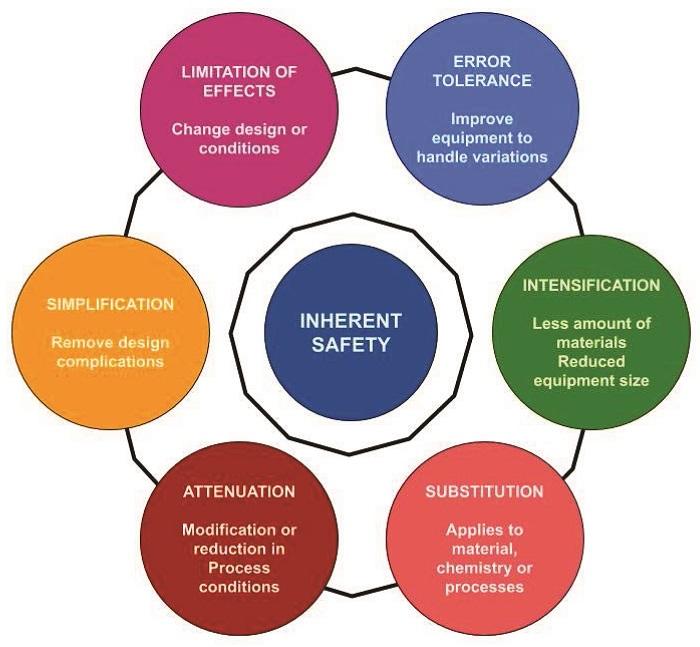

This leads to the concept of ‘Inherently Chemical Safer Plants’. The Inherent Safety Structure which is part of the conceptual process synthesis structure consists of three parts: Hazard Identification, Hazard Evaluation, and Inherent Safety Evolution. Chemical business has an inherent hazard which should be mitigated by designing and operating plants safely.

Safer Design

Safer Design

- If we could design a process with fewer hazards, then the process would be simplified, and the safeguards reduced.

- This is the essence of inherently safer design—to eliminate hazards rather than to provide complex safeguard hierarchies around the hazards.

- An inherently safer plant (Fig 2) uses the elimination of hazards to prevent accidents rather than depending on control systems, interlocks, redundancy, special management systems, complex operating instructions, or elaborate procedures. Inherently safer plants are tolerant of errors; are generally cost-effective; and are simpler, easier to operate, and more reliable.

If the industries develop, design, operate and control a chemical process such that the consequence is reduced because of different chemistry, chemicals, conditions or simplicity, wouldn’t the safety of the plant be improved? Is this not better than layers of protection?

Four Categories of Chemical Safety Process Strategies

1. Inherent

2. Passive

3. Active

4. Procedural

I will discuss them one by one:

1. Inherent

This approach to chemical plant safety involves the elimination or significant decrease of hazards within the plant, by applying changes in process conditions, chemistries, and technologies used throughout the process, making sure that these cannot be easily changed or bypassed without changing the process or the plant design itself. Inherent safety can be brought into the plant, for instance, by the substitution of a flammable solvent by water is an excellent case of an inherent safety strategy: by switching one for the other, the potential of fire is eliminated, exposure to toxic vapors, and possible contamination of wastewater in one simple step are avoided.

2. Passive

A strategy that typically revolves around process and equipment design features, passive chemical safety strategies reduce the frequency or consequence of hazardous events taking place. For example, building blast walls around process equipment can prevent explosions from causing uncontrollable damage to surrounding areas and workers; also, using equipment with higher pressure rating than their processes typically demand can ensure that dangerous spikes in pressure are controlled naturally.

3. Active

These strategies require an active response, typically from engineering controls or human operators. Unlike inherent or passive safety strategies, these mostly occur once the event is taking place, and are a safeguard for the plant, its workers, and its surroundings before disasters can occur. Some examples include sprinklers and similar fire suppression systems, pressure relief devices, purging systems, flares, and feed interlocks, which close valves and shut off pumps to prevent overflows.

4. Procedural

4. Procedural

The final strategy is not actually an engineering control, but instead an administrative control: operating procedures, safety rules and responses, safe work practices, and training are all included in procedural chemical safety strategies. An excellent example involves the training and responses expected of operators within a plant’s control room, who must always be prepared to take action when abnormally high temperatures or significant change in operational pressure take place.

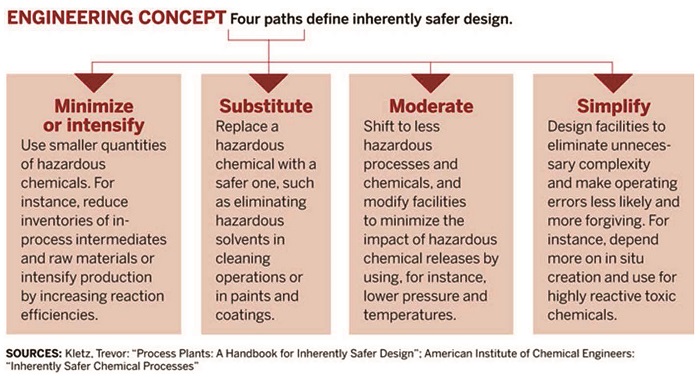

The four engineering concepts in a nutshell are abbreviated as M, S, M, S which are explained in figure 3.

Safety Culture and Way Forward:

- In an industrial zone or cluster of industries, it should be mandatory for all factories to let the neighbours know what chemicals and materials they use and process, without disclosing the trade secrets. Remember there is no secret about an accident. For instance, the maximum operating conditions and preparedness for accident prevention and propagation must be known to authorities. This will help the nearby sites to be ready with emergency plans should there be an accident or fire or catastrophe.

- All degree programmes in Chemical & Biological Sciences, Engineering & Technology must teach compulsorily Chemical Process Safety and Risk Management Courses and have in-plant training of 6 months. Those who work in chemical and allied industries must undergo a course on Process Safety and Risk Management. Refresher courses must be conducted. Industry must facilitate such training for their own benefit. On the Board of Directors, a Director for Innovation and Process Safety must be appointed under whose guidance a team works at each manufacturing site.

- There is a need of more Centres of Excellence for Research & Innovation on Process Safety and Risk Management in some leading Institutes.

- A National Chemical Safety Board ought to be established by GoI, directly reporting to the PMO like the OPCW to investigate all accidents and create a database and give guidelines to the industry. It is NOT disaster management board. This Board must be independent from the Pollution Control Boards and must have experts who can help in critically analyzing all accidents in the past across the globe and giving guidance at the time of accident propagation. The requirements of the Chemical Industry are totally different and Industries Associations must pursue this matter in their own interest because the Atma Nirbhar Bharat (Self Reliant India) will give them an opportunity to make new chemicals and materials including polymers. The China factor must be exploited to be part of the UDS 5 trillion.

- And last but not the least, public awareness programmes must be conducted from time to time by industries or their associations, for the benefit of colonies and communities nearby which can be directly affected, should there by an accident.