Abstract

The pressure on companies in the European Union is increasing, to become part of the European Union Green Deal. Chemical companies in Europe often implemented programmes, which are even more aggressive, and outlined concrete plans on how to become climate neutral even long before the deadlines set by the European Union. As European chemical companies started inviting their Asian supplies to be part of the programme, it is just a question of time till the same requirements will apply to Indian chemical manufacturers as well, directly or indirectly. Instead of waiting till they cannot avoid anymore the unavoidable, Indian chemical companies should consider to be at the forefront of this movement and benefit from the increasing importance of being sustainable to improve their image in the perception of their European customers, and as a result their market position in Europe

Indian chemical companies, which supply to Europe understand that doing business with European companies is more than offering the right quality at an attractive price. Without a EACH registration, the potential customer will not even test a product. And even if a company passes this hurdle, it is necessary to create enough confidence during lab and plant trials, that the customer is sure of the technical capabilities. In addition, the supplier needs to prove over a longer period of time his logistical performance, and he needs to have a good partner in Europe, who is capable of answering customer queries and complaints in a satisfactory way, so that the company is seen as a reliable partner which European customers trust. Nevertheless, not even this will be sufficient in the future. The global challenges resulting from climate change made us all aware, that the way we live our life and how we do business needs to change. For Europe, the European Union decided that they want to implement a number of measures to make our life greener and summarises this bundle of measures in a plan called the European Union Green Deal. There are a number of points which are addressed in this European Union Green Deal.

The policy areas which are in focus are:

The policy areas which are in focus are:

1. Biodiversity: Measures to protect the fragile ecosystem

2. From Farm to Fork: Ways to ensure more sustainable food systems

3. Sustainable agriculture

4. Clean energy

5. Sustainable industry: Ways to ensure more sustainable, more environmentally respectful production cycles

6. Building and renovating: The need for a cleaner construction sector

7. Sustainable mobility: Promoting more sustainable means of transport

8. Eliminating pollution: Measures to cut pollution rapidly and efficiently

9. Climate action: Making the European Union climate neutral by 2050

As it is the most time critical issue currently, the major discussion is around the topic of climate neutrality. As key milestone of the European Union Green Deal the European Union decided to become climate neutral by 2050.

But some of the member states are even more aggressive. The parliament in Germany has decided that the country should become climate neutral by 2045. One consequence of this court ruling is also that measures have to be defined for the entire period until the target is achieved. So, it will not be an option to just set the target and after 10 years to postpone the end date.

But some of the member states are even more aggressive. The parliament in Germany has decided that the country should become climate neutral by 2045. One consequence of this court ruling is also that measures have to be defined for the entire period until the target is achieved. So, it will not be an option to just set the target and after 10 years to postpone the end date.

Naturally, the pressure on companies in the European Union is increasing to contribute as much as they can to the European Union Green Deal and in particular to reduce CO2 emissions. At a first glance it might look as though 25 or 30 years are a long time to get things done, but especially for the chemical industry, and also for other industries driven by long investment cycles, this period of 25 or 30 years until the target has to be achieved is not very long. In particular, for companies with a capital intense product portfolio, the implementation of climate neutrality will be a huge challenge. Nonetheless, in spite of these challenges some companies are even more aggressive. Lanxess for example committed itself to becoming climate neutral by 2040.

Due to the political targets most of the European chemical companies started focused programs to accelerate the reduction of CO2 emissions. That this is a major challenge, not only because of the capital intensity, becomes clear when you know that the industry in Europe is under pressure to reduce CO2 emissions for some time already, particularly in Germany, which is also driven by high energy costs, and there are not many low hanging fruits anymore. This means, European companies must look into each and every detail of their activities. They need to look for options to reduce and/or compensate CO2 emissions, also along the input side of their value chain, and this does not only mean the energy consumption, but also the raw material procurement.

From an Indian perspective one might now argue that these are all only long term initiatives, and companies can wait and watch as their business will not be impacted in the next 5 years. However, unfortunately, this is not the most likely scenario. As I am also the European representative for some chemical products of one of the largest Indian business houses, I was recently invited by one of the major European chemical companies to attend a virtual conference on how this company wants to achieve climate neutrality and what the European company expects from their Asian suppliers on this journey. The message was very clear: if you want to continue to supply long term you will have to contribute to this target. How much and by when is certainly depending on how the purchasing market for the concerned products look like, but, to wait and watch is a strategy, which will for sure weaken the competitive position. From my point of view, it is just a question of time until the stricter requirements will apply to Indian chemical manufacturers as well, be it because more and more customers will push for it or because India will set itself targets to become climate neutral sooner than expected as of today.

As a supplier to European customers, Indian companies thus have two options:

1. Only follow the requirements of their customers and wait till they cannot avoid the unavoidable with the risk that their position vs competition is weakening or

2. Be at the forefront of this movement and implement sustainability measures ahead of competition to improve their image in the perception of their European customers and as a result their market position in Europe.

But, I personally feel there is really no choice, as an additional risk is already on the horizon: During the federal elections in Germany in September this year most likely the Green Party will gain a lot of votes and might even become the strongest party in Germany. In this case we will see even more pressure on the industry. But as the Green party also cannot afford to risk millions of well paid jobs in Germany, they will certainly fight for a regulation in the European Union to allow only imports of products, which are produced as per European Union climate standards. And especially for products where the competitiveness in Europe will not be given anymore after implementation of drastic measures (e.g. steel production based on H2 technology) the EU might finally decide to only allow imports of climate neutral manufactured products.

But, I personally feel there is really no choice, as an additional risk is already on the horizon: During the federal elections in Germany in September this year most likely the Green Party will gain a lot of votes and might even become the strongest party in Germany. In this case we will see even more pressure on the industry. But as the Green party also cannot afford to risk millions of well paid jobs in Germany, they will certainly fight for a regulation in the European Union to allow only imports of products, which are produced as per European Union climate standards. And especially for products where the competitiveness in Europe will not be given anymore after implementation of drastic measures (e.g. steel production based on H2 technology) the EU might finally decide to only allow imports of climate neutral manufactured products.

As the topic of climate neutrality cannot be avoided anyway, it will be therefore the more promising strategy not to wait till competition has gained the competitive advantage, but to be proactive in addressing the challenges and gain the competitive advantage itself. But, how to reach the target of climate neutrality or at least a significant reduction in CO2 emissions? To ensure a faster and stringent implementation in the companies, it will be very important to set aggressive targets from the top management and to involve the whole company in the implementation. Each Manager needs to see the importance of the CO2 reduction in their targets, and their variable compensation, and each and every employee should understand the importance, not only for the survival of the company, but also as part of their efforts to make our planet and the population suffer less from natural disasters resulting from climate change.

As the topic of climate neutrality cannot be avoided anyway, it will be therefore the more promising strategy not to wait till competition has gained the competitive advantage, but to be proactive in addressing the challenges and gain the competitive advantage itself. But, how to reach the target of climate neutrality or at least a significant reduction in CO2 emissions? To ensure a faster and stringent implementation in the companies, it will be very important to set aggressive targets from the top management and to involve the whole company in the implementation. Each Manager needs to see the importance of the CO2 reduction in their targets, and their variable compensation, and each and every employee should understand the importance, not only for the survival of the company, but also as part of their efforts to make our planet and the population suffer less from natural disasters resulting from climate change.

Concerning the detailed approach for the reduction of CO2 emissions this is strongly dependent on the product portfolio of each company, but here are some general ideas I would like to outline:

1. Energy consumption: The cheapest and most efficient way to reduce CO2 emissions is to reduce power consumption. This means avoid power losses and look for more efficient equipment. You will sometimes be surprised how fast the pay-back for such measures is. Where all these options have been leveraged already the next step is to look for efficiency increase within the verbund of your site. Some units might generate heat, others might require it. The usage of efficient heat exchangers and also heat pumps where it makes sense will bring down CO2 emissions further.

2. Source of energy: Even though natural gas is available and more environmentally-friendly, in many places of the world coal is still the preferred way to run boilers, to generate electricity or to run co-generation plants. Because coal is globally very cheap this is a very cost-efficient way to produce heat or electricity. Unfortunately, from a CO2 perspective this is the worst choice.

But, with the increasing purchasing cost of CO2 credits or surcharges on the procurement cost of coal this advantage of coal will disappear sooner or later. This means not only from an environmental point of view the replacement of a coal fired against a gas-based boiler or co-generation plant will be attractive, but also financially it will be beneficial soon. But even though the use of this bridging technology will result in CO2 savings, it is not a long term solution and will not bring down CO2 emissions to zero.

A much better option would be to run a chemical plant with heat generated by a biomass based boiler and electricity generated from windmills and solar panels. This concept will work well if your plant has access to cheap agricultural waste, and if your energy requirement is not too big. Otherwise, to manage the procurement, and handle the required volumes of biomass will be too challenging. Concerning the supply of renewable electrical energy this can be done through own investment in solar power plants and windfarms, work with an energy supplier who guarantees that he supplies only power from renewable energy sources or a combination of both.

A much better option would be to run a chemical plant with heat generated by a biomass based boiler and electricity generated from windmills and solar panels. This concept will work well if your plant has access to cheap agricultural waste, and if your energy requirement is not too big. Otherwise, to manage the procurement, and handle the required volumes of biomass will be too challenging. Concerning the supply of renewable electrical energy this can be done through own investment in solar power plants and windfarms, work with an energy supplier who guarantees that he supplies only power from renewable energy sources or a combination of both.

The highest standard from an environmental point of view will only be to run the full plant on renewable electricity, which also means the heat generation will be done electrically from renewable energy sources. This is what BASF for example is planning to do for significant parts of their main site in Ludwigshafen. In a recent announcement BASF explained that they want to invest together with a large power company in the largest offshore wind park in the world. The investment volumes will be €4 billion and 80 percent of the power generated in this wind park will be directly supplied to the Ludwigshafen site in which even crackers are planned to run on renewable electrical energy. Just to underline the magnitude of this conversion: It means the demand of electricity in BASF’s Ludwigshafen site will at least triple from the current 20 Terawatt hours, which will be as much as 15 percent of all electrical energy generated by windmills today in Germany. Additional CO2 savings potential will be realised using green hydrogen.

The highest standard from an environmental point of view will only be to run the full plant on renewable electricity, which also means the heat generation will be done electrically from renewable energy sources. This is what BASF for example is planning to do for significant parts of their main site in Ludwigshafen. In a recent announcement BASF explained that they want to invest together with a large power company in the largest offshore wind park in the world. The investment volumes will be €4 billion and 80 percent of the power generated in this wind park will be directly supplied to the Ludwigshafen site in which even crackers are planned to run on renewable electrical energy. Just to underline the magnitude of this conversion: It means the demand of electricity in BASF’s Ludwigshafen site will at least triple from the current 20 Terawatt hours, which will be as much as 15 percent of all electrical energy generated by windmills today in Germany. Additional CO2 savings potential will be realised using green hydrogen.

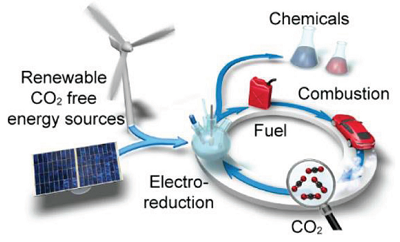

Unfortunately, it has to be accepted that in general the usage of green hydrogen will be limited to areas where there is surplus of electrical energy or a strong political support and subsidies to compensate for the high energy consumption of H2O hydrolysis. Under normal conditions the process is just too inefficient and costly although from an environmental point of view the production of Hydrogen from water and electricity from windmills is just perfect.

3. Product portfolio adjustment: Active portfolio management under the aspect of reduction of CO2 emissions is an additional way to improve the CO2 balance for the company. By looking at the product portfolio along the two dimensions profitability and CO2 impact you might identify candidates with lower profitability and high CO2 impact you might want to shut down or sell. Equally important can be the sale of production facilities which generate byproducts with high CO2 equivalents if these cannot be avoided.

4. Research and development: It is also important to not ignore the chances, which can result from focused research and development efforts. Looking for more efficient production processes, the avoidance or reduction of unwanted by-products or the reduction of water consumption are targets which will help to make the company consume less energy and thus, greener.

5. Measures to compensate CO2 emissions: If all other activities did not solve the CO2 problem the company faces, this needs to be considered. Investments in climate protection projects are one way of doing this. It is just important to ensure that these are additional projects to have a net effect on the climate.

These efforts will certainly have major financial challenges for companies, and so it is also up to the political decision makers to financially support this transformation or at least create the right framework that these investments will pay off faster. But independent of this aspect it should not be forgotten that a company, which is doing such an effort faster has a major competitive advantage in this new normal and certainly also a major image gain. And very often these projects will finally turn out to be financially positive, be it through the avoidance of buying carbon credits or lower running cost and/or maintenance. But at least equally important is that our children and grandchildren will be thankful to us for having had the far-sightedness to keep the planet as livable as it is today in spite of all the challenges we faced.