Researchers from Wales, UK, produced methanol from methane through simple catalysis that allows methanol production at low temperatures using oxygen and hydrogen peroxide.

Professor Graham Hutchings, Director of Cardiff Catalysis Institute, said: “Our process uses oxygen; effectively a ‘free’ product in the air around us, and combines it with hydrogen peroxide at mild temperatures which require less energy.”

“If a stable supply of methyl radicals can be established—for example, by incorporating a very small amount of hydrogen peroxide into the reaction mixture—then the selective oxidation of methane to methanol using molecular oxygen is entirely feasible,” said Christopher J. Kiely, the Harold B. Chambers Senior Professor Materials Science and Chemical Engineering at Lehigh.

The researchers found that for this particular reaction to proceed they needed the Au-Pd nano-particles to exist as free-floating colloids in a very weak hydrogen peroxide solution into which they injected pressurized methane and oxygen gas.

“Usually when we use Au-Pd nanoparticles as catalysts they are nearly always dispersed on high surface area oxide supports such as titania,” said Kiely. “In this case, however, the presence of the ceramic support turned out to be highly detrimental.”

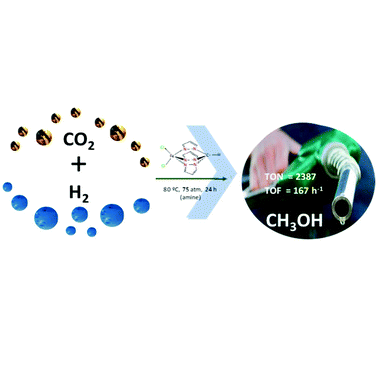

In the chemical industry, methane is currently indirectly converted to methanol via the production of synthesis gas (CO + H2) at high temperatures and pressures, which is an expensive and energy-intensive process. The most promising processes discovered to date for the direct conversion of methane to methanol have tended to be complex, inefficient, and often require very high temperatures and aggressive reaction environments.

“The new simplified approach we have demonstrated brings us a step closer to making a direct conversion of methane to methanol a practically viable proposition,” said Kiely.