Abstract

In today’s industrialized world, not just treatment of industrial wastewaters is essential to protect ecology and environment, but providing safe drinking water is also a challenge. In view of these, the removal of contaminants, be it organic, inorganic or bio-contaminants, is a serious problem requiring various forms of technologies. The chemical industry requires unique techno-economical methodologies for different industrial sectors and for diverse nature of pollutants, low to high concentrations in effluent streams, for the desired extent of removal, foot prints in the assimilation of technology, less maintenance and flexibility of operations. The advanced oxidation methodologies that destroy organic pollutants to an extent of complete mineralization and hydrodynamic cavitation are gaining wide attention in this regard. CSIR-NCL’s new cavitation device vortex diode, which is based on vortex flow, is quite effective in destroying various organic pollutants and also harmful microorganisms from water. The applications can be many in industry sectors such as dyes and textile industry, pharmaceutical industry, fertilizer industry and also for drinking water treatment. The CSIR-NCL’s technology is now commercialized and is being successfully used in many industries.

Dr. Vinay Bhandari is a Chief Scientist in the Chemical Engineering & Process Development Division of CSIR- National Chemical Laboratory, Pune, with more than 32 years of research experience apart from 2 years of industrial experience. He has more than 300 publications/presentations, authored 2 books (“Industrial wastewater treatment, recycling and reuse”, Elsevier, 2014 and “Hydrodynamic Cavitation: Devices, Design and Applications”, John Wiley & Sons Inc., 2022), and filed 25 patents (12 patents granted). He has developed 4 technologies based on hydrodynamic cavitation- for Disinfection of water (SWASTIIK); for Industrial wastewater treatment (commercialized in India/abroad) and for Desulfurization of fuels. He is recipient of several prestigious awards including Green & Sustainable Chemistry award, SERB-IGCW-2017 and IGCW-2023. His desulfurization work received GYTI award for Technological Innovation, conferred by the Hon. Vice President of India in 2019. He is also consultant to many industries specifically in the areas of Industrial wastewater treatment and Separation Processes.

Divya Dixit is a Research Scholar at CSIR-National Chemical Laboratory, Pune and has contributed to devising newer methodologies in water and wastewater treatment, especially in the development of dual activity and surface coted cavitation reactors that drastically enhance the efficiency of conventional hydrodynamic cavitation processes. She has published 6 research papers in reputed international journals and has won several awards including the prestigious Industrial Green Chemistry World (IGCW) award in 2023.

Introduction

W ater and wastewater treatment is a complex problem, especially when many new emerging pollutants are getting detected in the surface waters, causing harmful effects of various forms in living species and also on environment. In earlier times, when the volumes and locations of industrial the volumes and locations of industrial wastewaters were limited and nature of pollutants was well known, many common technologies such as coagulation to adsorption were quite useful in treating the wastewaters prior to the safe release/use. In recent times, many new organic pollutants have emerged in the form of specialty chemicals in sectors such as dyes/textiles, polymer industry, chemical fertilizers, pesticides, insecticides and due to increased use of pharmaceuticals, cosmetics and such specialty molecules. Many of the chemical industries are water intensive and generate huge quantities of wastewaters.

The advances in chemicals sector are driving occurrence of pollutants that are largely refractory in nature having difficulty in biodegradability and also are difficult to degrade using the conventional technologies. The problem of refractory pollutants is largely pertinent to industries generating less volumes of wastewaters such as pharmaceutical industries. The conventional thought process of characterising wastewaters in these industries in terms of only chemical oxygen demand(COD) and biological oxygen demand (BOD) can be quite inadequate and wastewater complexity can be quite severe compared to common chemical industry wastewaters. In known industry segments, the selection of technologies is largely on the basis of techno-economic feasibility using combinations of well-established technologies whereas for emerging pollutants removal, the selection is required specifically on the basis of treatability of wastewaters and newer technologies are essential, given the difficulties in the degradation of emerging pollutants using conventional methods.

The established effluent treatment technologies include charge-based separation methods such as coagulation, physical and physico-chemical surface forces-based methods such as adsorption, chemical methods such as oxidations, catalytic oxidations, photo-oxidations etc., size-based separation methods such as membranes and biological treatments of the type aerobic and anaerobic treatments. As a thumb rule, when the BOD contribution is high, the biological treatment is a good choice given the low cost of treatment. Sewage water treatment is one example where activated sludge process (ASP) is in use for over 100 years. For the treatment of high strength wastewaters, anaerobic treatment gives advantage in the form of generated biogas and efforts need to be made to have such increased value addition in the existing processes.

The commonly used coagulation – a charge neutralization process through the addition of coagulants such as inorganic or organic types that reduces the repulsive forces on the colloidal matter for forming agglomerates and thereby removal by simple settling- is quite useful in the part removal of pollutant load. The effectiveness of the coagulation process primarily depends on the nature of the coagulant and in most cases hybrid forms of coagulants are suggested for low sludge volumes, operation over a wide range of pH, fast settling and low cost. Chethana et al. reported significant improvements using appropriate combinations of bio-coagulants with conventional coagulants such as alum, ferric, and aluminium based coagulants to lower doses of bio-coagulants (up to one-third) and to increase acssus chemeng.5b 01553).

Adsorption, though, is a well-established process, the solution to environental problems for pollutants removal require slow-cost adsorbents, such as biomass derived adsorbents for high selectivity and without regeneration problems. Newer developments suggest use of biomass derived materials, nano-bio-composites, superpara-magnetic nanocomposites for easy separations and such adsorbents with multifunctional character for sustainable wastewater treatment or in effective removal of different organic pollutants, dyes and also for disinfection of water (Saumaya et al., 2018, https://doi.org/10.1016/j.jenvman.2018.08.028). Catalytic degradation processes, starting from Fenton oxidation, wet air oxidations, photocatalytic processes etc., typically have disadvantages in the form of suitable catalyst, real life applicability and generation of other hazardous by-products, apart from the cost of the catalyst and life.

For the removal of emerging/persistent organic pollutants, the conventional technologies largely have limited applicability. The removal methods, including membranes, have the biggest disadvantage as they tend to transfer problem from one point to other by generating secondary waste and therefore cannot be termed as sustainable technologies. In view of low concentrations of the emerging pollutants and high risks associated with these, even at low concentrations, destructive treatments technologies such as advanced oxidations processes and electro-oxidation have to be employed. Hydrodynamic cavitation here offers one specialized form of advanced oxidation without use of conventional catalysts. Hydrodynamic cavitation in recent years is getting extensively explored for various applications and appears to be highly promising in diverse applications such as biomass processing, desulfurization of transportation fuels, food processing etc. However, the most promising application of hydrodynamic cavitation appears to be in water and wastewater treatment. Recently, Ranade and Bhandari have evaluated applications of different methodologies in industrial wastewater treatment, including hydrodynamic cavitation (Industrial wastewater treatment, recycling and reuse, 2014, https://doi.org/10.1016/C2012-0-06975-X).

CSIR NCL’s Technologies for Water and Wastewater Treatment

Hydrodynamic Cavitation

Hydrodynamic cavitation is one important class of cavitation from real life applications point of view,the other less common forms being acoustic cavitation, particle cavitation and optic/laser cavitation. The cavitation technology, in general, implies formation of oxidising species and the generated oxidising agents help in the oxidative degradation of the organic pollutants. The technique is specific form of advanced oxidation process and is mainly applicable to the degradation of organic pollutants. Since the chemical industry has diverse nature and contributes to various forms of organic pollutants- from simple organic molecules to complex specialty molecules and emerging pollutants, the cavitation technology is highly relevant to the wastewater treatment problems of different chemical industries.

Hydrodynamic cavitation technology employs suitable mechanical cavitation device (reactor) for effecting sudden pressure drop and generation of cavities and for subsequent oxidation due to generation of hydroxyl radical through water splitting. The cavitating devices can be classified as those with moving elements (Rotor-stator type) and those without moving elements (e.g. orifice, venturi and vortex diode). The different types of reactors, the design details and theoretical performance evaluation in different types are well described in the recent book by Ranade, Bhandari et al. (2023) where different applications of hydrodynamic cavitation including that in effluent treatment are highlighted (Hydrodynamic Cavitation: Devices, Design and Applications, https://www.google.co.in/books/edition/Hydrodynamic_Cavitation/8L-XEAAAQBAJ?hl=en&gbpv=0). Though the cavitation technology was known for several decades, the practical real life applications are getting appreciated only recently and the readers may find the above reference highly useful in not just acquainting with the techniques, but also for exploring possible applications in the area of water and wastewater treatment.

Vortex Diode for Effluent Treatment

We, at CSIR-NCL, have developed water and wastewater treatment technologies based on advanced oxidation process – hydrodynamic cavitation where a specialized cavitation reactor was designed using vortex flow in cavitation, termed as vortex diode (US9422952B2, IN397769, EP2766314, PCT/IN2012/000676, US9725338B2, IN338553, PCT/IN2020/051007, WO 2021/111476 A1, US2021111476).The technology has been licensed to M/s VIVIRA Technologies, Pune and a large number of units of CSIR-NCL designs are presentlybeing used in different industries. The vortex diode is a simple mechanical device of specific design without any moving elements. It consists of a tangential inlet, circular chamber for vortex generation and an axial outlet. Water/wastewater stream enters tangentially into the chamber and forms a strong vortex. The design is such that there is a sudden pressure drop to an extent that part of the liquid flashes into vapor forming cavities or bubbles (Fig. 1).

The cavities are allowed to grow and finally to collapse in the designed manner. The collapse of the cavities, termed as implosion (opposite of explosion), generates extreme temperature (~10000 K) and pressure (~1000 atm) conditions at the point of implosion, causing water to split homolytically generating hydroxyl radicals. The hydroxyl radicals are highly oxidising species and oxidise the organic pollutants, envisaged results being complete mineralization, forming carbon dioxide and water. It has been observed that mineralization is common in hydrodynamic cavitation using vortex diode of conventional type, whereas, it can also results in formation of by-products apart from mineralization in vortex diodes having catalytic activity; though the number of by-products is typically much less than that observed in conventional catalytic degradation processes. However, these aspects need to be investigated in the preliminary experimental investigations for viability since there are no theoretical predictions available till date.

The vortex diode for effluent treatment has many advantages compared to most conventional devices in terms of high degradation efficiency, lower pressure drop and consequent lowered cost of operation apart from less/ no maintenance, less clogging due to large open area and easy scale-up up to 40 m3/h. The technology is useful for degradation and removal of variety of organic pollutants and thus for reduction in COD and ammoniacal nitrogen (Bhandari et al., 2021, https://doi.org/10.1016/j.ultsonch.2020.105306)

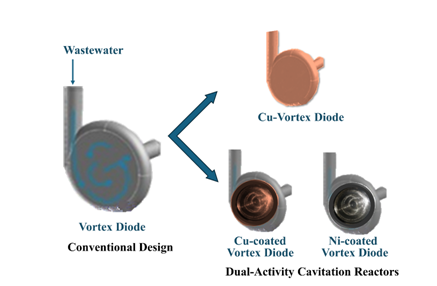

Fig. 1. Cavitation process and CSIR-NCL’s cavitation reactors for industrial applications Dual Activity and Surface Coated Cavitation Reactors for Water and Wastewater Treatment

The vortex diode as a cavitation reactor certainly offers significant advantages in terms of lower pressure drop, higher degradation efficiency, less maintenance and most importantly lower capital as well as operating cost compared to the conventional devices. However there are still limitations and the technology still finds difficult to present itself as a stand-alone technology to provide complete solution to wastewater treatment. Similar to the catalytic oxidation process, it would be instructive to add catalytic activity to the conventional cavitation without addition of the external catalyst. This philosophy was translated in the form of dual activity and surface coated cavitation reactors where the reactor itself could be catalytic metal or the internal surface can be coated with catalytic metal specific to the degradation of the pollutants (Fig. 2).

The proof of concept was successfully established by using copper vortex diode for the degradation of cephalexin where extraordinary enhancements in the degradation were observed due to catalytic action of copper in Cu-vortex diode compared to the conventional hydrodynamic cavitation under similar operating conditions, especially using process intensification with hydrogen peroxide (Dixit et al., 2023, https://doi.org/10.1016/j.cherd.2023.02.03). Similarly, the surface coated vortex diodes using the internal coating of catalytic metals such as copper and nickel were extremely effective compared to even the conventional vortex diodes for the degradation of various pollutants, and degradation to an extent of 100% could be accomplished within minutes. The new reactors clearly highlight the utility of the dual function cavitation reactors over the conventional devices for increased efficiencies and subsequently significantly reduced costs in industrial wastewater treatment. Also, the technology is suitable for destructive removal of harmful refractory pollutants,consequently providing sustainable processes for environmental pollution control.

Fig. 2. Transformation of Conventional Reactors into Dual Activity Cavitation Reactors

Applications of CSIR-NCL’s Vortex Diode Technology for Real Life Industrial Wastewater Treatment

Distillery Industry Wastewater Treatment

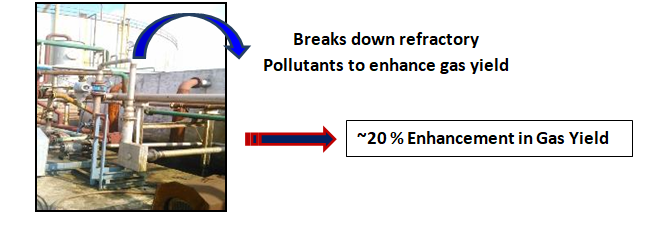

Distillery wastewaters are typically characterized with very high values of COD (>1,00,000 ppm) and high BOD (~50000 ppm or more). It also has high ammoniacal nitrogen content. Here, the vortex diode technology is quite useful in converting part COD to BOD to enhance the gas yield, to an extent of 20% based on the real industry data.For example, in one real life installation, and for distillery effluent characteristics of initial COD of ~125,000 ppm for the flow rate of 50 m3/h, and increase in the gas yield up to 22% was reported. The installation is simple, as can be seen from the Fig.3, where the effluent can be passed through the vortex diode using the suggested process conditions of pressure drop/ flow rate prior to sending to anaerobic digester. The technology is also useful for removal of ammoniacal nitrogen.

Fig. 3. Application of Vortex Diode for Distillery Wastewater Treatment

Pharmaceutical Industry Wastewater Treatment

Due to the advances in the medicinal field, many new API pollutants, whose regulatory status is largely unknown, have been detected insurface waters and also in the drinking water. The persistent and refractory nature of such emerging pollutants is dangerous to the ecosystem. The conventional treatment methods are largely inadequate to effectively remove these pollutants; their destructive removal is especially important in view of the hazardous nature of many of the pollutants even at extremely small concentrations. Vortex diodes and hydrodynamic cavitation is quite effective in this regard, but with process intensification. The efficiency of hydrodynamic cavitation was enhanced by introducing catalytic action within the cavitation reactor, either by changing the construction material or by coating the internal surface of the reactor with an appropriate catalytic metal.For example, degradation of ciprofloxacin using normal advanced oxidation methods and also conventional vortex diode yields only up to 20% degradation, whereas the surface coated dual activity vortex diode can yield 99% degradation using process intensifications of the type pH modification or hydrogen peroxide addition.

Recently, Dixit et al. (2023, https://doi.org/10.1016/j.cherd.2023.10.002) reported that copper and nickel coated vortex diodes can provide complete degradation of antibiotics such as Cephalexin andCiprofloxacin within just 5 min, the performance being far superior over the conventional reactors under similar operating conditions. The technology was also effective for the complete degradation of common diabetes drug, metformin using these surface coated cavitation reactors (2023, https://doi.org/10.1016/j.cep.2023.109572). In view of the high cost of treatment of the conventional methods including that for advanced oxidation processes and electro-oxidation, the developed vortex diode hydrodynamic cavitation technology can provide techno-economically viable solution at cost lower by an order of magnitude.

Fertilizer Industry Wastewater Treatment

Fertilizer industry has different units producing effluents with varying organic pollutants and their concentrations. Hydrodynamic cavitation using vortex diode was found to be highly effective in treating a stream of very high COD (> 1,00,000 ppm) where ~85% removal of COD was reported (2016, https://doi.org/10.1080/19443994.2016.1186399). The technology was also effective in the removal of ammoniacal nitrogen from various high ammoniacal nitrogen containing effluents of different plants. The use of dual activity cavitation reactors has not been reported so far on such effluents, but it can be expected that these can perform better than the conventional devices.

Dyes/Textile Industry Wastewater Treatment

Dyes and textile industries produce effluents many of which contain refractory pollutants. In view of the small to medium size of the industries and varying products of specialized nature, specific process integration methodology needs to be developed for lowered overall cost of ETP. The nature of the dye and characteristics of the wastewaters are critical to the success of the degradation methodology and preliminary evaluation at laboratory pilot plant scale is essential to assess the efficacy of the techniques, optimization of the parameters etc. Again, needless to mention, the new dual activity cavitation technology can be highly useful for degradation of reactive molecules. The low-cost hydrodynamic cavitation technology here can provide techno-economically feasible solution and can be easily integrated in the existing ETP.

Drinking Water Treatment

Safe drinking water is essential to living and for preventing waterborne diseases such as diarrhea, dysentery, typhoid, and polio. The recommendation of WHO, “The potential health consequences of microbial contamination are such that its control must always be of paramount importance and must never be compromised”(WHO, 2019, https://www.who.int/) is clear in this regard. While, there are physical methods such as heat treatment, UV disinfection, membranes etc., the chemical methods such as chlorination are largely prevalent with close to 95% use worldwide for water disinfection. The chemical methods have main disadvantages such as generation of disinfection by-products many of which are carcinogenic apart from ineffectiveness in eliminating all harmful microorganisms. We, at CSIR-NCL, have developed SWASTIIK technology for water disinfection- Safe Water and Sustainable Technology Initiative from Indian Knowledgebase, by integrating the ancient knowledge of Ayurveda and our indigenously developedhybrid hydrodynamic cavitation technology. The technology has the potential to offer alternative to existing disinfection processes, mainly chlorination with cost-effectiveness. The technology is effective in eliminating practically all the harmful bacteria, including antimicrobial resistant (AMR) bacteria (Mane et al., 2020, https://doi.org/10.1016/j.ultsonch.2020.105272.; https://doi.org/10.1016/j. ultsonch.2019.104820).

The developed technology is unique of its kind to successfully demonstrate the use of commonly used natural oils having antimicrobial activity, such as peppermint oil, ajwain oil etc., in a very low concentration of less than 0.1%. The combined impact of cavitation and oil results in complete and instant cell destruction through the rupture of cell wall, oxidative damage and possible DNA denaturation. The oil can be easily separated and recycled/reused. The estimated cost of treatment is believed to be ~Rs. 2.5/m3 or 0.25 Paise/L.The new dual activity cavitation reactors can also provide another useful and effective alternative to drinking water treatment without the use of any chemicals/oils. Thus, in view of low cost and ease of operation, the technology can be employed not only for the drinking water treatment plants, but also can be implemented for household/point of use applications.

Summary

Industrial wastewater treatment requires new advanced technologies for effective removal of the refractory pollutants and for increased cost-effectiveness. CSIR-NCL’s hydrodynamic cavitation technology and vortex diode, dual activity cavitation reactors and surface coated cavitation reactors offer indigenous technologies for wastewater treatment, providing promising alternative to many existing processes, mainly advanced oxidation processes. The surface coated vortex diodes can also provide potentially useful alternative to existing chemical methods such as chlorination for drinking water treatment. The developed technology alternatives are easy to implement, require less capital and operating costs, practically no maintenance and offer easy scale-up. It can be used for the degradation of pollutants, in isolation or in combination with many processes. It certainly can offer benefits in the existing effluent treatment plants for reduced operational costs apart from desired contaminant removal.

Wastewater as a source of energy should be considered where applicable for converting part COD into BOD and vortex diodes are highly suitable for the treatment of high strength wastewaters to enhance gas yield.The CSIR-NCL’s vortex diode and new dual activity/surface coated cavitation reactors can find wide applications in many industries such as for distillery wastewater treatment, pharmaceutical industry etc. in the form of techno-economically feasible solution to industrial wastewater treatment.

Acknowledgement

The authors, Dr. Bhandari and Ms. Dixit, would like to acknowledge the financial support from Department of Science and Technology, India and Council of Scientific and Industrial Research, India for the research in the area of water and wastewater treatment.