Abstract

The advent of Industry 4.0 recognizes the impact of paradigm shifting digitalization in the chemical industry. This article discusses the applications of various elements of digitalization and its implications on R&D

In 2015 we had published our view on the future of R&D in the chemical industry. Since then technologies such as lab automation and artificial intelligence (AI) are being adapted more rapidly than before. This has widespread implications for the R&D processes that chemical companies use and provides new opportunities for leading companies to use digitalization to expedite data analytics and discovery.

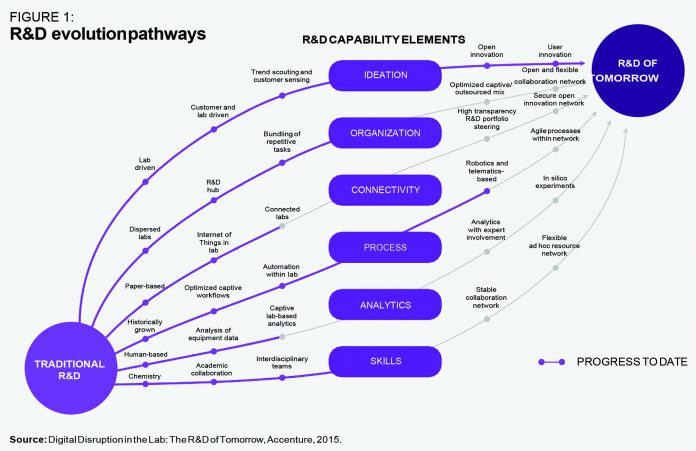

As in our earlier original paper, we had introduced six evolution pathways (Figure 1). Over the past few years, chemical companies have progressed at varying speeds along these pathways, with some universal advancements:

Ideation

Open innovation and co-creation with customers have become the norm for most players.

Connectivity

The use of the Internet of Things (IoT) and connected labs is on the rise, but often information is still fragmented across global R&D sites.

Analytics

Analytics and AI initiatives are advancing; however, access to consolidated, quality data remains a challenge.

Organization

Many companies still maintain captive R&D functions and hesitate to utilize flexible collaboration networks, leaving value on the table.

Process

Automation is increasing as part of Industry 4.0 initiatives.

Skills

Industry players are hiring new profiles (e.g., data scientists), but hesitate to build flexible external networks.

Since chemical companies generate enormous amounts of data in R&D, connectivity and analytics are two particularly promising development pathways. These categories require adopting new approaches to access integrated, high-quality data, which is particularly important for companies where massive data harmonization initiatives have reached their limits.

Given the digital technology advancements in AI, it is now possible to build cutting-edge data access solutions that bracket existing enterprise R&D systems; apply automation and machine learning for data ingestion; and offer human-centered, intuitive access to the data via virtual agents and chatbots. This enables a new way of working in the chemical lab.

From Legacy to Digital: New Ways of Working with Data

While many chemical companies have developed digital strategies and implemented “lighthouse” projects in some business functions, R&D appears to be stuck in traditional experimental design and data handling.

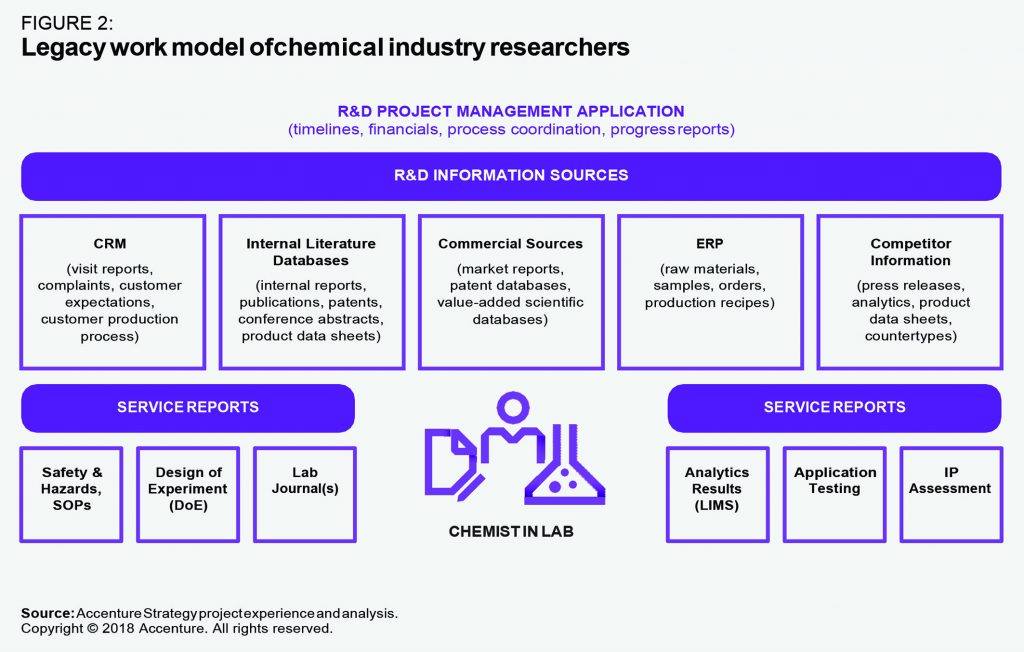

As shown in Figure 2, researchers and lab technicians still spend large amounts of time navigating through various internal and external data sources—including Laboratory Journals, Laboratory Information Management Systems (LIMS), Standard Operating Procedures (SOPs), Regulatory Data, Analytics, Product Data Sheets, Scientific Literature, Customer Relationship Management (CRM) Information and Patent Databases.

While some results are shared between these various sources, most information is not transferred. Thus, the chemist must retrieve and aggregate the information required to make the best-educated decision. Furthermore, employees also tend to rely on experience accumulated within their own micro-environment.

While this way of working may have previously been successful, the ever-growing amount of data, pressure from innovative competitors and new technological opportunities are starting to overwhelm R&D employees — and the way of working must change. Thus, it is time to rethink information management in the lab setting and use supportive digital technologies to quickly harvest and improve the value generated from these myriad data sources.

The main challenges within R&D from a data perspective are threefold: highly fragmented information due to data systems that diverge by chemical application, inhomogeneous data quality and a limited ability to monitor external activity effectively. Many existing data management systems were also developed without human-centricity in mind, thus they are highly complex to use and seldom accepted by new employees.

However, by integrating recent technologies such as lab automation and AI, these barriers can be bridged, leading to intuitive access to data and freeing up R&D time for creativity. Chemical executives are increasingly recognizing this—51 percent of industry respondents to Accenture’s Technology Vision 2018 survey confirmed they are planning to apply AI solutions in R&D over the next two years. As a result, chemical companies will leapfrog into an entirely new way of turning their R&D data into business value.

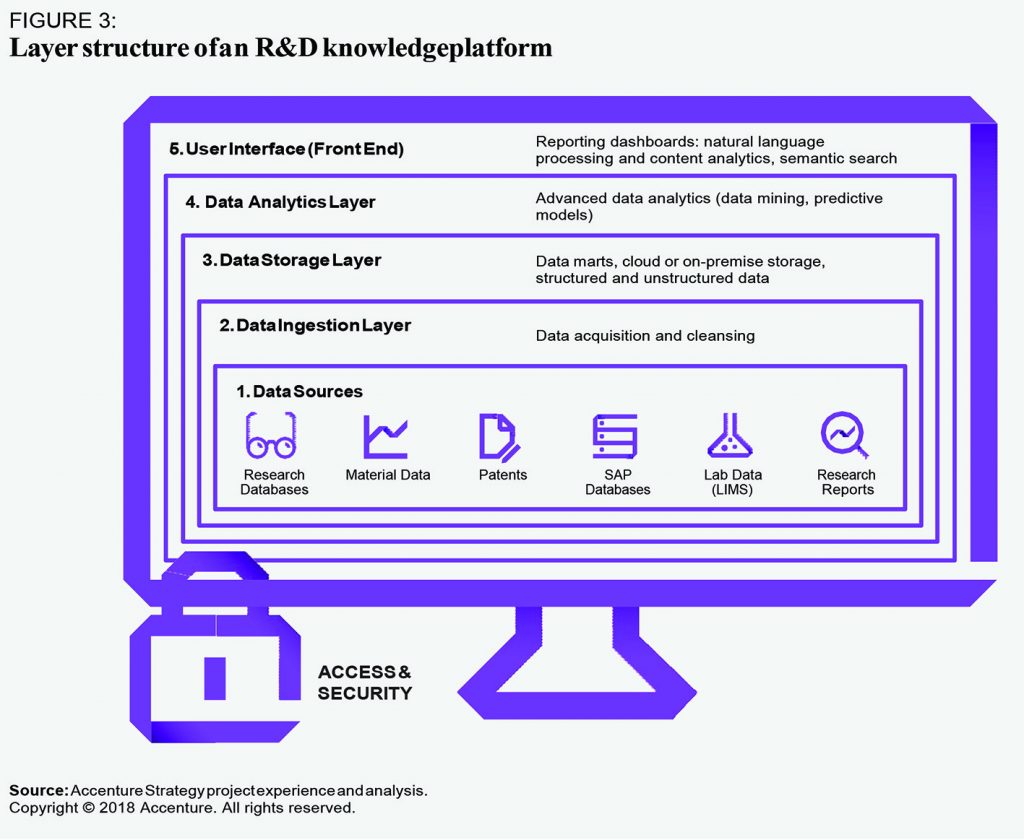

Deploying AI makes it possible to extract and effectively index both structured and unstructured data. This enables companies to automate the integration and cleansing of such diverse information as lab reports, images, spreadsheets, text documents or presentations.

Combined with well-established technologies such as optical character recognition, even the digitization of handwritten documents becomes economically feasible.

Taking this a step further, the knowledge platform (Figure 3) created by the above processes allows researchers or portfolio managers to evolve to a whole new way of working. For instance, employees might pose questions in natural language to a chatbot that accesses advanced analytics behind the scenes to provide answers within seconds. Possible questions include:

Based on historical data, how will a new formulation perform in the lab, in production or in an application?

Has a similar experiment been conducted previously, in the company or elsewhere? What was the outcome? What was missed at the time? Is an internal expert available?

Where would this product be suitable for other applications and new markets?

In addition, intelligent systems can be trained to analyze external information and perform tasks such as detecting potential patent infringements or providing developers with insight on relevant market activities. Furthermore, with centrally managed information technologies, R&D can be fully integrated into a new business IT architecture (e.g., SAP S/4HANA) and benefit from shared, consistent master data and more direct interaction with other already digitally-enhanced functions.

Business Case Drives Outcomes

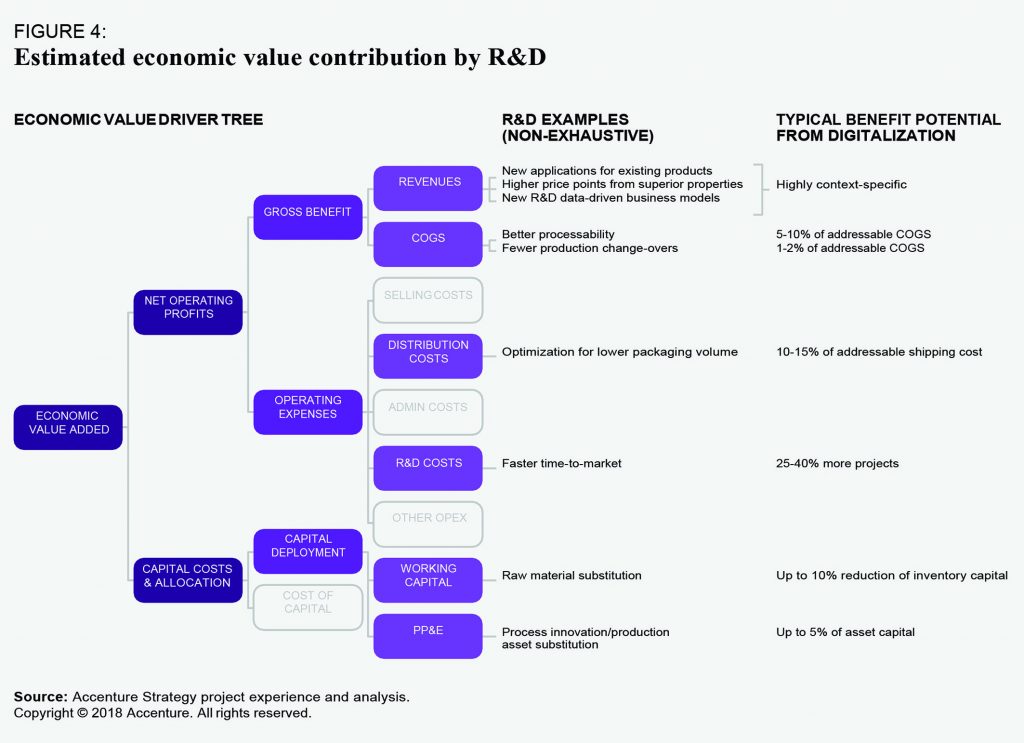

In addition to a more responsive R&D process, R&D digitalization comes with a strong supporting business case—the costs of digitalization, including the buildup of software, hardware and infrastructure as well as of changing established operating procedures, will be outweighed by significant efficiency gains.

Applying digital measures to R&D can drive economic value through three specific effects.

First, leveraging digital capabilities in R&D can speed the innovation process by up to 15 percent, based on Accenture Strategy project experience. Examples include faster preparation and experimentation through lab automation and robotics, and a quicker ability to complete research and collect relevant information through ubiquitously available data.

Second, the improved availability and analyzability of R&D data makes it easier to estimate the technical feasibility of development projects and optimize resource allocation, leading to a higher success rate on R&D projects.

Third, being able to use digital technologies to make better decisions throughout the entire innovation funnel increases the R&D portfolio value.

While each case needs to be evaluated in its individual context, based on Accenture Strategy project experience, R&D digitalization addresses multiple economic value drivers, as shown in Figure 4.

Implications for R&D

Planning and designing a technical platform for R&D data digitalization should follow a use-case-driven approach, to avoid creating a fancy technical solution that does not provide substantial benefits. Rather than just consolidating available data and adding AI and analytics functionality on top, chemical companies need to approach platform design and implementation pathways based on the requirements of R&D stakeholders.

Automation and AI technology is available and ready to use. However, there is no one-fits-all solution. The implementation timeline and effort depend on the diversity of R&D data and applications as well as on the desired functionality.

In addition, companies wishing to improve their R&D capability need to think through the human implications of a new technology for their R&D operating models and employees. Collaboration processes might evolve to include more cross-fertilization among businesses and regions. Traditional R&D roles such as idea scouting or experimental design and execution may no longer be needed. By contrast, more technical capabilities might be required to operate the data management system, maintain data ingestion and continuously evolve analytics use cases based on the needs of the R&D stakeholders.

Considering this shift of required skill sets, a chemical company should also evaluate which capabilities to build internally and which to source from an ever-growing external R&D ecosystem.

Given the rapid advancements in technology and significant potential business benefits, R&D digitalization should be a “must-do” on every company’s agenda. The time is now for chemical industry players to think about how to unlock the value hidden in their data and take R&D performance to the next level.

This article is reprinted entirely from Accenture, which retains full publication rights.

To digitalize your R&D lab please contact:

Saurabh Tayal

Accenture India

Email: saurabh.tayal@accenture.com