Aspen Technology, Inc. is a global leader helping Industries meet the challenges of several challenges on sustainability, energy transitions, resource efficient productions etc. AspenTech solutions address complex environments where it is cirtical to optimize the asset design, operation and maintenance lifecycle.

Excerpts from the interview

Q 1. Chemical Industry Digest (CID): As is well known by now, Industry 4.0 digital technologies are a game changer. How transformational is it going to be for chemical and allied industries?

Ron Beck (RB): For most chemical sites, the production environment, while being run safely and profitably today, is far from optimized. For instance, most chemical processes can achieve 15–30% incremental energy efficiency with corresponding reduction in carbon emissions.

The manufacturing executive of a major Southeast Asian chemical concern, agreed with me on that opportunity at a recent executive panel in Singapore. Almost all of this can be achieved through pervasive digitalization of both the supply and demand side of energy use. At the same time, many high value chemical processes still have challenges in terms of detailed understanding of the reasons for variability in their reactor processes.

These can be impacted significantly by Industrial AI. For example, Dow Chemical presented in a public forum regarding how they are solving production challenges in a complex reaction unit through hybrid models (combining first principles models with AI), increasing yields by 10% with immediate benefits in profitability. The company explained this exciting digitalization result in a public webinar we sponsored. The recording is available online. In both supply chain and production areas, digitalization is strategic in prioritizing actions that can be taken to both decarbonize and to reduce water use.

Finally, R&D is seeing renewed focus globally in chemical organizations, as companies race to develop and commercialize new materials based on bio – and renewable feedstocks. In R&D and early design, concurrent engineering workflows are enabling leaders to do techno-economic evaluations much faster and better, and then to scale up at an accelerated rate using concurrent, automated, and AI enabled workflows.

Q 2. CID: What are the AspenTech core software offerings or solutions for chemical and allied industries?

RB: AspenTech provides a broad and deep range of digital software solutions used strategically across the chemical industry. The company’s engineering simulation and digital twin models solution, based around the Aspen Plus system, is used in areas ranging from base chemicals, to petrochemicals, to polymers, and to performance chemicals. These are used by leading companies as an end-to-end digital thread, from R&D through production to maintenance.

In production, the multivariate control solution Aspen DMC 3 is a standard solution in both conti-nuous and batch processes, with well-established ability to drive production to higher margins, higher yield, better quality, and lower waste.

AspenTech’s supply chain solutions (Aspen Collaborative Demand Manager and Aspen Supply Chain Management Insights) are used for both demand-driven and operational excellence driven business lines. The company’s asset performance management solutions apply data science, root cause analysis, and AI to improving asset uptime. AspenTech’s digital grid and microgrid solutions are helping companies to electrify and decarbonize operations.

The company has multiple ongoing projects and is embedding industrial AI across this broad portfolio, including areas, such as the Dow example (provided earlier), as well as providing guidance to operators in production optimization, supply chain, and prescriptive maintenance.

Q 3. CID: What are the key benefits that your digital solutions provide to chemical companies embarking on digitalization? And what should chemical companies do to accelerate digitalization?

RB: AspenTech’s chemical customers are seeing several areas of key benefits. In today’s cost-constrained chemical environment, digital solutions can provide immediate benefits in reduced operating costs, improved production uptime, reduced variability in product streams, and better on time delivery. Strategically, a huge area of benefit is time-to-market for new chemical products, and another is agility in adjusting to global supply chain instabilities. A third crucial area that advanced digitalization creates benefits is training and upskilling the new generation of workers.

Many chemical companies have experienced brain drain with the most experienced operators, engineers, and R&D staff retiring – turning key roles over to a new generation. Digitalization and industrial AI are playing a key role in providing guidance to these newer work forces, in operating safely and in taking advantage of operating history to inform them of the best possible operating strategy today and going forward.

Q 4. CID: Sustainability as well as major transitions in energy feedstocks etc are major challenges and opportunities. To what extent can digitalization and software solutions enable these transitions in an overall context? What is the digital transformation needed in chemical companies?

RB: In simplest terms, here are some key areas where digitalization will strategically help chemical companies to excel in this new environment:

If you can’t measure it, you can’t improve!

Measuring carbon emissions, energy and water use, and greenness of the supply chain using digital modeling and visualization does and will have a huge impact. We have worked with one European downstream company who has implemented this, and two others who are in process. It gives immediate, companywide visibility to whether sustainability targets are on track, and where the areas for technical and management focus should be.

The key underlying concept is that real-time enterprise visibility turns operational and supply chain reporting into actionable decision support. Digitalization “mobilizes” the data to support operational and sustainability excellence. With the data available, as industrial AI becomes more and more impactful, solutions that create value for your situation can be adopted.

Also, many of the topics involving circularity, decarbonization and efficiency require adoption of new processes and technologies. To do that at scale, and with no interruption in business, a digital thread across the lifecycle of an innovation project is critical.

Q 5. CID: Now let’s take AspenTech’s solutions in specific areas: How does it contribute to sustainability and digitalization in chemical industries?

RB: Digital twins (based on engineering simulation) and advanced process control software are reducing energy consumption (and corresponding reduction in carbon emissions) by 5–15% (of the 30% I mentioned at the outset) depending on the type of chemical process.

Multivariate analysis and advance process control solutions are improving product quality by identifying the root causes in the process of product variability and improving operations to eliminate that variability.

Utilities and energy modeling software are enabling companies to plan and execute strategies to maximize use of renewable power, to maximize green content at lowest cost, and to track and manage water use.

Supply chain planning and execution software is able to track “green” content in the supply chain and trace it from source to end user.

Microgrid software is enabling chemical operators to incorporate renewable and low carbon electricity sources into operations, additionally improving the confidence in uninterrupted operations in the face of increasingly stressed regional power grids.

Asset performance management solutions provide advanced warning of equipment degradation, reducing the frequency of unplanned downtime that are emissions-emitter events.

Q 6. CID: How do your solutions enable energy transitions, shifts to renewables, use of biomass feedstocks etc.?

RB: Let us take the example of incorporating bio-feedstocks into chemical processes. One practical approach is to mix between 10–20% bio feedstocks with conventional hydrocarbon-based feedstocks. This involves new ground for most producers, in terms of ensuring the quality and operability of processes. Bio feedstocks are more variable and introduce chemical characteristics that can impact operating strategies and maintainability. A process that was run for years without advanced digital tools, such as digital twins and advanced process control, now needs to be modelled and managed with these digital technologies. The digital twin will provide insights into the behavior of the new mixed feedstocks, while the advanced process control will allow optimized operations based on the insights from the digital twin. The company is currently working with several European chemical companies to incorporate data analytics to understand behavior of the new feedstock regimes and hybrid models.

To support innovation and introduction of new processes in this area, we have added capabilities to support bio-feedstocks. For example, we have expanded our physical property libraries to incorporate characteristics of typical bio-feedstocks and we have developed sample models to get process engineers started in developing models of these systems for use in project work and in digital twins.

Q 7. CID: In what ways can your solutions accelerate the hydrogen economy?

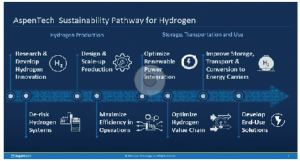

RB: For the hydrogen economy, and many other similar areas, AspenTech has comprehensive digital solutions that cover the entire value chain as well as the entire capital project lifecycle. To communicate this, the company has developed a hydrogen sustainability pathway.

For example, AspenTech has a systems-level modeling software system (Aspen Fidelis) that models system alternatives at the frontend of planning, enabling the evaluation of alternative technologies, alternative processes, and electrical routes.

In another example, the company has developed detailed models of the range of hydrogen electrolysis approaches. These detailed models are seamlessly incorporated into models of the entire balance of plant as well as the renewable power supply.

AspenTech also provides a distributed energy resources management solution to manage the provision of renewable power – buffered by battery storage – to optimize the provision of power evenly to green hydrogen and ammonia units.

There is much more to this digitalization story, but those are a few examples. The ultimate goal of applying digital technology to hydrogen production and use is to drive the cost of hydrogen from about $6/kg to $1/kg over the next 10 years.

Q 8. CID: There is a lot of media highlight on AI as being revolutionary. To what extent is it hype or real in terms of implementation? What role does AI play in AspenTech’s solutions and in chemical industry specific areas?

RB: AI is definitely already beginning to disrupt some industries, and some applications are beginning to be adopted and create value in the chemical and energy industries.

The key challenge in the chemical and energy industry is to ensure that the AI that is adopted provides realistic and correct recommendations, that operators and engineers remain in charge to ensure the validity of the output of the AI, and that the AI is transparent and explainable.

It is also important to select the right technology for the right problem. AI is needed to solve some, but definitely not all problems, and is o

verkill for many business processes in the chemical industry.

AspenTech believes that we are in a unique position to provide these solutions, because we are well positioned to combine AI with models based on engineering fundamentals, putting crucial guardrails around the AI applications so that the results follow the laws of chemistry, physics, electricity, and geoscience, and so that the outcomes are safe.

We call that approach of domain-expertise guardrails, “Industrial AI,” and we believe it is fundamental to successful adoption of AI in the right places in the chemical industry.

We have released over 25 different industrial AI capabilities, deployed within our existing strategic systems that are widely used in industry. These solutions are creating value in areas, such as (a) business agility, (b) guidance to operations and technical workers, and (c) automation of time-consuming processes.

For example, Corteva Agriscience implemented AspenTech’s Industrial AI Hybrid Models in Aspen Plus within a day. These models enabled them to monitor their heat exchange columns, linked to crucial chemicals production columns. The company has calculated that the solution is already yielding cost-savings amounting to over USD 10 million per year in improved quality and yield and lower maintenance costs.

Nissan Chemicals is using similar hybrid models to provide accurate insights into their ammonia reformer units, which saves the company 2% in steam usage (and associated carbon emissions) per year. Another company, IOCL, is using hybrid models in one of their refining units, as a soft sensor to predict viscosities in the unit, enabling them to improve process performance and yields.

Q 9. CID: Do asset optimization, process optimization, plant and machinery reliability play significant roles in sustainability in addition to vastly improving manufacturing efficiencies and productivity?

RB: Absolutely, Process optimization is particularly important. Most chemical operations can gain significant energy efficiency, potentially up to 30% in total. Process optimization can provide about 5% of that total energy efficiency and carbon emissions reduction. Predictive maintenance solutions also play a significant role. Unplanned shutdowns, cost by unexpected equipment degradation or failure, are very significant sources of emissions over the typical year of a plant’s operations. Using prescriptive maintenance to turn unplanned downtime into scheduled maintenance can avoid those emissions events. Further, there is a spike in energy use any time equipment or units are restarted.

Q 10. CID: What are the key challenges you face in getting industry to incorporate high tech digital solutions such as yours? What changes do you expect/want from chemical industry companies so that there is ease of adopting such digital technologies?

CF: Digitalization is not simply a technology adoption activity. The organization needs to be ready to take full advantage of the digital solution. This means that organizational change and readiness is as important as digital technology itself.

One leading chemical company presented a fantastic success story of implementing digital twins using AspenTech’s Aspen HYSYS process simulation platform, explaining that the key breakthrough is the understanding that they needed to instill a “culture of modeling.” There are several key aspects of this.

The most fundamental is to understand the breadth of value that can be unlocked with digitalization and therefore, the value in fully training the spectrum of potential users, of encouraging these user communities to explore new value opportunities, to share best practices, and to also understand that the technology will increase the value of their work – help and augment the workers, not replace them. This is especially important as industrial AI solutions are introduced. In the complex and safety conscious world of a chemical manufacturing site, industrial AI is not going to replace workers. It is going to provide an expert co-pilot and advisor who is at the disposal of helping the worker to make better, more strategic decisions, faster. It is about instilling that culture.