Dürr has enhanced its modular EcoProWet pretreatment system by introducing a new cathodic electrocoating (EC) module—EcoProWet EC. Designed with compactness and scalability in mind, this next-generation wet system addresses the challenges of space and efficiency in automotive painting, especially for small to medium production capacities of up to 30 units per hour.

Compact Design Meets High Performance

In automotive paint shops, pretreatment remains one of the most space-consuming processes due to the size of tanks required for cleaning and coating. Traditional systems are typically designed to handle the largest car body dimensions and longest dwell times, resulting in high space and cost demands.

To overcome this, Dürr developed EcoProWet—a flexible, modular pretreatment solution that significantly reduces space requirements. Building on the earlier success of EcoProWet PT, which focused on pretreatment, the new EcoProWet EC module now incorporates the cathodic electrocoating step.

Advanced Cathodic Electrocoating: Efficient and Scalable

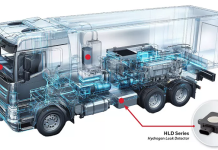

Following pretreatment, car bodies are transferred to the EcoProWet EC electrocoating module. This stage applies a uniform primer layer to the entire vehicle body, ensuring corrosion protection and creating a reliable base for subsequent paint layers.

Unlike traditional systems, EcoProWet EC features compact, standalone basins rather than a single continuous paint-filled tank. Two independently controlled pendulum towers lift car bodies from the roller conveyor and smoothly immerse them into the bath. With an immersion angle of up to 60 degrees, the system offers automakers flexibility to tailor the process to different vehicle models.

Each dip tank can handle up to ten units per hour. During the three- to five-minute immersion, the energized paint creates a consistent, high-quality coating across the vehicle surface.

Modular System for Scalable Production

Dürr specifically designs the EcoProWet system for manufacturers with small to medium production volumes. Its modular configuration supports gradual scaling—from 7.5 up to 30 units per hour—without requiring major operational changes or facility modifications.

This staged expansion approach allows manufacturers to align capacity with demand while optimizing paint usage and operating costs. In addition, the compact layout frees up valuable space on the factory floor and enables a more flexible, efficient paint shop design.

A New Standard in Sustainable Vehicle Painting

As per the press release, EcoProWet EC features a reduced footprint, lower material consumption, and modular scalability. It sets a new benchmark for space-saving, cost-effective, and sustainable pretreatment and coating solutions in the automotive industry.