India is striving to become a global semiconductor manufacturing hub by leveraging supportive government policies, rising demand, cost-efficient production, and strategic partnerships with Western nations.

Government Incentives Driving Investments

The government has introduced a $10 billion incentive program to boost domestic semiconductor manufacturing. The initiative covers around 50% of project costs for chip and display fabrication plants, as well as testing infrastructure. Additionally, some states offer extra incentives of up to 20%, raising total fiscal support to nearly 70%.

These measures have attracted over $18 billion in investments across five major projects. One of the largest is Tata Electronics’ $11 billion chip fabrication plant, developed in collaboration with Taiwan’s Powerchip Semiconductor Manufacturing Corporation (PSMC).

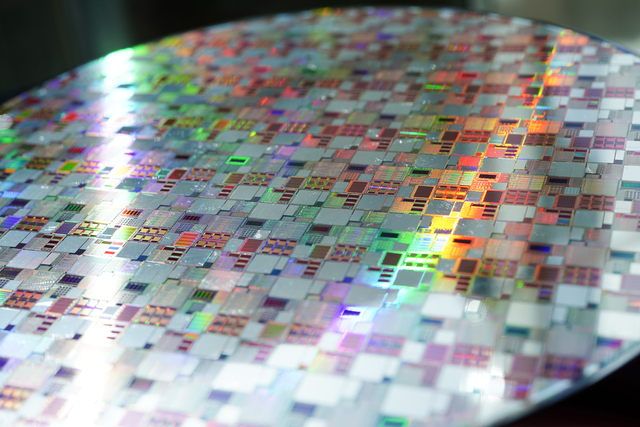

Building a Comprehensive Semiconductor Supply Chain

India’s semiconductor strategy goes beyond chip fabrication. The government aims to build a complete supply chain, covering everything from raw material production to high-end packaging and testing.

A strong semiconductor ecosystem requires a steady supply of critical materials such as silicon wafers, specialty gases, and chemicals, most of which India currently imports. To reduce this dependency, policymakers are working on initiatives that encourage domestic production of these essential inputs.

Strengthening Semiconductor Design and Packaging

India already holds a strong position in semiconductor design, with major global players like Intel, Qualcomm, and NVIDIA operating large design centers in the country. Now, the government is focusing on integrating this expertise into a local manufacturing ecosystem.

Another priority is the development of advanced chip assembly, testing, and packaging facilities. By ensuring that chips manufactured in India undergo final processing within the country, the government aims to reduce reliance on foreign facilities.

Global Partnerships to Boost Growth

Collaboration with international players is a key aspect of India’s semiconductor expansion. The government is actively engaging with countries like the US, Japan, and Taiwan to attract technology transfers and joint ventures. By developing a network of suppliers, component manufacturers, and logistics providers, India aims to establish a self-sustaining semiconductor ecosystem.

Overcoming Challenges to Become a Semiconductor Powerhouse

Despite its strong ambitions, India faces significant challenges in becoming a global semiconductor hub. These include developing a mature supply chain, acquiring advanced manufacturing expertise, and competing with established players worldwide. Addressing these issues will be crucial for India to achieve long-term success in the semiconductor industry.

A Promising Future for India’s Semiconductor Industry

With substantial investments, strategic policies, and a focus on comprehensive ecosystem development, India is paving the way to becoming a major semiconductor manufacturing hub. As reported by manufacturingtodayindia.com, by building on its past manufacturing successes and strengthening its supply chain, India is positioning itself as a key player in the global semiconductor market.