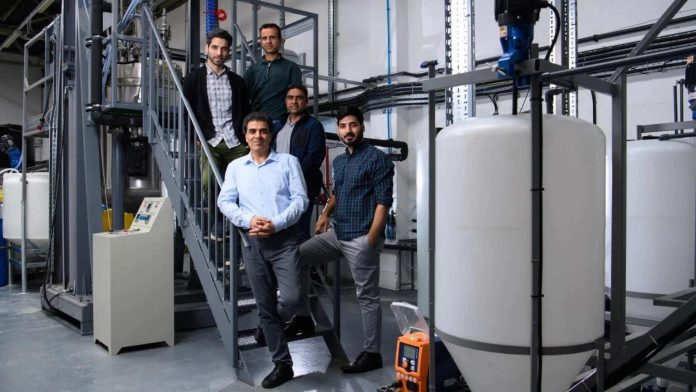

Integrals Power, a cutting-edge company specializing in battery nanomaterials, has begun production of advanced lithium iron phosphate (LFP) and lithium manganese iron phosphate (LMFP) cathode materials at its innovative new pilot plant in the UK. The development marks a significant step forward for the UK’s battery industry and is anticipated to boost domestic battery manufacturing, contributing to the country’s net zero goals.

After successful lab tests, Integrals Power has launched the UK’s first pilot plant dedicated to producing their proprietary high-performance LFP and LMFP nanomaterials. The facility boasts an annual production capacity of 20 tonnes—equivalent to the battery needs of approximately 250 electric vehicles.

The output will be primarily used for evaluation by global cell suppliers, battery manufacturers, and vehicle makers. This move is also a strategic advantage for the UK’s battery sector by cutting down on carbon emissions, enhancing supply chain resilience, and addressing geopolitical challenges such as import tariffs on electric vehicles and their components.

The quality of Integrals Power’s LFP materials is evidenced by their ultra-high purity, verified through advanced X-ray diffraction technology that analyzes the chemical composition and lattice structure, which are crucial for battery performance.

Behnam Hormozi, Founder and CEO of Integrals Power commented, “Launching production at our new pilot plant is a pivotal achievement. It allows us to manufacture our high-performance LFP and LMFP cathode materials at scale. This facility is among the first of its kind in the UK, providing the advanced resources needed for the UK battery industry to support sustainable growth in electromobility”.

Hormozi also highlighted that the pilot plant’s flexibility and scalability are designed to accommodate various grades of Lithium Iron Phosphate nanomaterials for different uses, from long-range electric vehicles to off-grid energy storage solutions. The facility is built to expand its production capacity in response to increasing global demand.

As reported by m2n-converting.com, the production process, which includes seven stages, takes up to 48 hours from raw material to finished samples ready for customers. Integrals Power sources all raw materials from European and North American suppliers, ensuring higher purity and performance in their LFP and LMFP materials compared to the predominantly Chinese-manufactured cathodes that currently dominate global production.