Abstract

Carbon neutrality across industries globally is the imperative today to address climate change.In this direction, recent COP27 deliberations once again underlined the necessity to mitigate emissions from carbon intensive sectors including chemicals. The chemical industry is one of the largest consumers of fossil fuels; and can play an important role in the energy transition with the aid of innovative technologies to ensure carbon neutral growth.

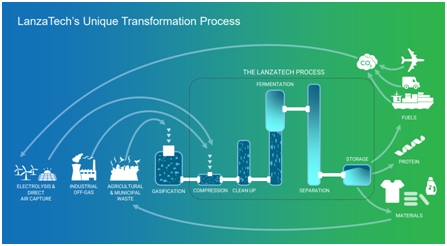

To achieve these ambitious climate goals, we need a systems-level solution drawing multiple sources of waste carbon and producing sustainable fuels & chemicals; today made from fossil carbon. A transition from oil refining to “carbon refining” is an opportunity for distributed sustainable production and industrial rebirth.

Carbon refineries can harness available high-volume, low-cost, carbon-rich resources like agricultural residues, landfill waste and industrial emissions to produce sustainable ethanol that could be sufficient to entirely displace many products made today from oil refining. LanzaTech;a leader in carbon capture and transformation is already working to make this vision a reality.

Globally, nations are developing strategies to replace chemical products with low carbon alternatives, this offers a tremendous opportunity to create new supply chains for renewable chemicals. Ethanol from waste carbon can be converted to ethylene (a key chemical building block) and further transformed into polymers, surfactants or polyester fiber. This creates a closed loop, circular carbon economy where carbon is reused rather than emitted and waste carbon is a valuable, sustainable raw material to make the things we use in our daily lives.

A vision at scale, the article will cover LanzaTech’s Commercial journey; CarbonSmart™consumer products and a way to enable a just energy transition. The UN Climate Change Conference(COP27) in Sharm el-Sheikh, Egypt,concluded with optimism as nations joined hands to support developing economies for ‘loss and damage’ caused by climate catastrophes. An incremental win from COP21, the developing economies will need more of such commitments to address climate challenges and accomplish the Just Energy Transition.’

The UN Climate Change Conference (COP27) in Sharm el-Sheikh, Egypt, concluded with optimism as nations joined hands to support developing economies for ‘loss and damage’ caused by climate catastrophe. An incremental win from COP21, the developing economies will need more of such commitments to address climate challenges and accomplish the ‘Just Energy Transition.’

According to IEA, despite all the interventions we are seeing today, the fossil carbon share will still stay above 60% by 2050 (from 80% today) in the energy mix[1].What is more alarming, this translates to just a 13% annual CO2 reduction by 2050,not enough to address climate change. With our focus always glued on the energy sector, chemicals, a significant consumer of fossil carbon,are often neglected in the climate debates.

Chemical production accounts for 12% of global oil demand[2]and is expected to increase significantly to meet rising polymers, material& fertilizers consumption.The chemical industry consumes about 50% of fossil carbon input as raw material or feedstock[3]. This,in turn, contributes to more than 900 MT of CO2 emissions annually just from the direct production of chemicals. The industry with a14% share of CO2 emission within the industry segment is classified as a carbon-intensive industry, thus requiring robust decarbonization efforts.

With our daily lives revolving around fossil carbon-derived fuels and products, it’s time we realize the detrimental impacts of continued fossil fuel use, especially on the environment and people. To achieve ourNet-Zeroobjectives and overcome climate despair, a large-scale, robust, rapid, and sustained effort must be made to re-tool our entire carbon economy.

Decarbonization is a requisite for the industry to attain carbon neutrality.The transition toward carbon neutrality will require the energy sector and energy-intensive industries like chemicals to invest in innovative technologies and create new value chains that enable a circular carbon economy where carbon is reused rather than wasted.

Directly recycling greenhouse carbon into everyday products through a process of biological gas fermentation is one of the most viable paths for a clean energy and sustainable materials future. Making low-carbon fuel (ethanol) and chemicals from waste carbon, such as industrial off-gases, agricultural residues, and municipal waste, to displace products made from petroleum is critical to overcoming the challenge of decarbonizing carbon-intensive industries.

The inherent flexibility of a biological process, like gas fermentation, allows a variety of waste streams to be readily available without adversely affecting food or land security. CO2, with the aid of Green H2 can further amplify this waste carbon feedstocks pool and be a game changer for energy security and GHG mitigation. Ethanol produced from waste has substantial emissions savings compared to fossil fuels and is competitive with plant-based ethanol without impacting land use or biodiversity. Carbon transformation technologies hold opportunities that can be applied across economic sectors, such as agriculture, industry, and waste management, as an essential strategy to reduce greenhouse gas (GHG) emissions and meet the nation’s energy, economic and environmental objectives.

The technology already exists at scale and is producing results with over 120 million liters of ethanol produced from steel mill emissions since 2018.

The world’s first refinery off-gas-to-sustainable ethanol plant in India is expected to come online by the end of 2022. Additional projects are also underway with other leading stakeholders in India to use agricultural residues for sustainable ethanol production.

Harnessing these multiple waste resources can produce more than 30 billion litres per year of sustainable ethanol that can help India to diversify its energy basket, produce SAF & chemicals, and harness domestic resources to address climate risks. Globally a market opportunity of over USD1.0 trillion, this innovative pathway can unleash investment in a sustainable supply-chain solution that will allow customers to meet sustainability goals and decarbonization mandates across the globe.

Harnessing these multiple waste resources can produce more than 30 billion litres per year of sustainable ethanol that can help India to diversify its energy basket, produce SAF & chemicals, and harness domestic resources to address climate risks. Globally a market opportunity of over USD1.0 trillion, this innovative pathway can unleash investment in a sustainable supply-chain solution that will allow customers to meet sustainability goals and decarbonization mandates across the globe.

Globally, countries, including India, are developing strategies to decarbonize the chemical industry and replace petrochemical products with low-carbon alternatives. For the energy-intensive chemical industry, decarbonization of the primary chemical segment is often looked at as low-hanging fruit towards decarbonization, as it contributes to 65% of energy consumption in the chemical and petrochemical sectors. For example, ethylene, a building block for other chemicals, requires[4] around 20 EJ worth of energy carrier feedstocks annually. To put this in context, the world’s primary energy supply[5] is more than 600 EJ where crude oil and natural gas hold 34% and 23% share of supplies, respectively.

With limited decarbonization options, the chemical industry needs faster diffusion of innovative technologies, new feedstocks, and decentralized models built on the foundation of a circular economy.

Manufacturers, major brands, and consumers desire sustainable product. Gas fermentation technology enables this by utilizing waste carbon to make the building block, ethanol. This can be further transformed into biopolymers, surfactants, or polyester fiber and used by consumer brands to make packaging, perfume, detergent, and household product cleaners.

Estimates show that these products reduce greenhouse gas emissions by over 70%compared to equivalent products derived from virgin fossil resources. This is critical when economies, including India, contemplate their low carbon growth trajectory and how to meet the increased demand for petrochemical products.

It is time to question where our carbon comes from. We should all take steps to launch a new Carbon Economy in India. As business leaders, we can use carbon transformation to rethink how we procure, use and dispose of carbon. And as consumers, we can choose where our carbon comes from.

In the quest for innovative technologies, we must ensure they benefit rural communities and traditional manufacturing centers. A new circular carbon model that includes waste carbon from wastes such as agricultural residues will support a more sustainable, equitable, and resilient economy.

To heal and repair the world takes time. And with innovation, strong partnerships,and the support of government leaders, we are ready to make the transition and celebrate a post-pollution future.

[1]IEA World Energy Outlook 2022

[2] https://www.iea.org/reports/the-future-of-petrochemicals

[3] https://www.iea.org/fuels-and-technologies/chemicals

[4]Mckinsey Decarbonization of industrial sectors: the next frontier Report

[5] https://unstats.un.org/unsd/energystats/pubs/documents/2022pb-web.pdf