Catalyst Plugging Mechanism

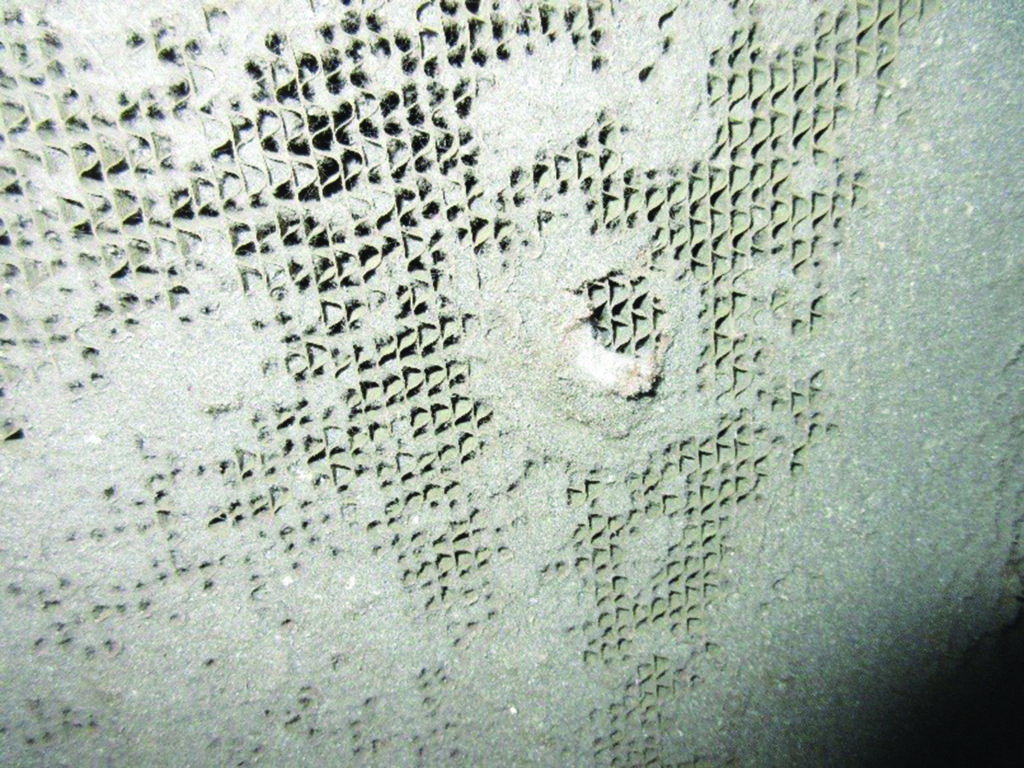

Hydrogen reforming is a process to produce hydrogen from a compound composed of hydrogen atoms. During reforming, a convection pass is used to heat the process which creates NOx. The NOx rich flue gas passes through an SCR reactor for reduction before being exhausted to the atmosphere. Lint-like fibres from the convection pass, and refractory liners create an obstruction that builds up and fouls the face of the SCR catalyst.

Buildup Costs Millions

The result is decreased NOx reduction, higher pressure drop across the catalyst, and ultimately decreased hydrogen output. Often, this buildup will require an unscheduled outage to manually conduct cleaning. This outage can take as long as five days at an estimated cost of $1 million per day.

Lab Study

Samples of ash collected from the catalyst were sent to the lab for testing. Microscopy images indicated hair-like particles as well as granular particles. These particles combine and create a “dryer lint”- like fibrous material.

Testing of several online cleaning systems such as sonic horns produced no discernible results in breaking up the media. However, the use of air cannon blasts sufficiently broke apart the mass. Various styles of screen material and design were then tested to determine the optimal pitch and diameter for operation in reformers.

Mitigation Method

The exact cause for the material being caught in the flue gas is unknown, and it is very difficult to pinpoint and address all locations where the refractory fiber may break loose. However, once the material breaks free and accumulates on the SCR catalyst, dP will increase and NOx removal will decrease.

Bringing the unit offline to vacuum the material is extremely costly and not an ideal solution, therefore units often run at a reduced output until the turnaround. IGS has installed nearly 100 NoNOx LPA screens in front of SCRs since the early 2000s, allowing companies to maintain better output. This screen, based on patented technology is available globally, including in India and South East Asia.

Case Study: Methane Reformer in Texas

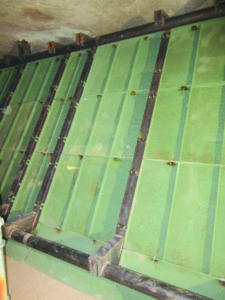

Based on these successes, IGS installed NoNOx Reformer Screens upstream of the SCR on a methane reformer in Texas in 2016. The screen is designed to capture these particles upstream of the SCR catalyst.

The screen pitch is designed smaller than the pitch of the catalyst, as it is critical to catch all particles which are too large to pass through the catalyst. Additionally, the screen functions as a flow aid. Therefore, IGS selected a screen system designed to achieve both sufficient filtration and flow optimisation. During the design phase, the pressure drop was also considered in selecting the screen pitch. The goal was to install a screen that would prevent buildup but also minimise pressure drop increase.

Air Cannons

Air Cannons are required because the particles tend to become trapped on the screen and block gas flow, much like fibers in a dryer lint trap. When this happens, the gas tends to bypass certain areas of the catalyst and increase NOx emission. The air cannon addresses this in two ways. First, they blast the particles, breaking them apart so that they are small enough to pass through the filter and the catalyst without harm. Second, the blast is aimed to push the remaining particles down to the lower collection area, where they will not impact performance and can be removed later during a planned outage.

Air Cannons are required because the particles tend to become trapped on the screen and block gas flow, much like fibers in a dryer lint trap. When this happens, the gas tends to bypass certain areas of the catalyst and increase NOx emission. The air cannon addresses this in two ways. First, they blast the particles, breaking them apart so that they are small enough to pass through the filter and the catalyst without harm. Second, the blast is aimed to push the remaining particles down to the lower collection area, where they will not impact performance and can be removed later during a planned outage.

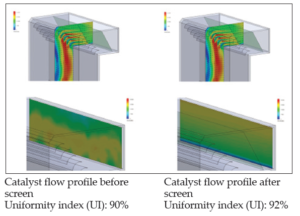

CFD analysis was performed with and without the screen in place, and the results showed that the screen improved the uniformity index from 90% to 92%.

Turnaround Impact

Due to the standardised modular design, IGS’s mechanical division can install SCR screens, Air Cannons, and access doors in less than a working week of critical path time. In this referenced case, all the work was performed within the time window of the preplanned outage and caused no impact to the turnaround schedule.

Prior to the screen installation, the typical startup sequence required utilising a “cheese cloth” to capture particles that break free during start up.

The new inline screen system eliminated the need for the cheese cloth by capturing all particles that were too large to pass through the catalyst. Before the screen installation, this practice was critical because the work performed during the outage resulted in dislodging particles larger that the catalyst opening. This process delayed full startup by roughly a day. Because of the installation of the screen, this cheese cloth startup process can be eliminated, saving roughly $1 million during each outage. This saving alone pays for the screen system!

Operating Assessment

Initially, the Texas plant did not experience any significant pressure drop increase across the catalyst, which was a significant improvement. Prior to the screen installation, the catalyst required frequent manual cleaning at a sizable cost. Initially, the plant opted to not utilise the air cannon system, which eventually caused buildup across the screen. This was predictable, as the screen was designed to capture the material and the air cannons were intended to sweep the buildup off the screen face and into the collection zone. However, even with the buildup on portions of the screen face, the distance between the screen and the catalyst was great enough so that the gas distribution recovered, resulting insignificantly improved SCR performance than without the screen in a built-up state.

Since air cannons were not used properly, the buildup on the screen face eventually did reach the catalyst face. When this was discovered, the air cannons on the screen were cycled and effectively broke apart the particles on the screen, allowing them to pass through the SCR without causing additional buildup. The particles were visibly seen coming out of the stack and no pressure drop increase was experienced across the SCR, confirming the successful air cannon cleaning.

To eliminate the risk of material passing through the screen were air cannons not operated regularly, after two years it was decided that a finer pitch secondary screen was to be installed. After installation of this secondary screen, all particle buildup on the catalyst face was eliminated.

Results

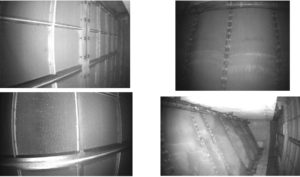

Below are photos of the catalyst face taken while the unit was online after more than a year of run time. They clearly show almost no buildup on the SCR itself, and the NOx reduction numbers remain constant. Due to infrequent firing of the air cannons, the secondary screen does experience some minor accumulation, however data indicates this does not impact the NOx removal or SCR performance.

This elimination of buildup and pressure drop resulted in the plant no longer having to run at a reduced output, has their ID fan running per design, has optimal NOx reduction of the process gas, and has increased the catalyst life. After recognising this success, the plant has purchased a second IGS screen system for its sister plant, to be installed in 2022.

This elimination of buildup and pressure drop resulted in the plant no longer having to run at a reduced output, has their ID fan running per design, has optimal NOx reduction of the process gas, and has increased the catalyst life. After recognising this success, the plant has purchased a second IGS screen system for its sister plant, to be installed in 2022.