Standard Glass Lining Technology Limited (SGLTL) has announced a strategic alliance with Japan’s AGI Group and its affiliate GL HAKKO to manufacture glass-lined shell and tube heat exchangers domestically. The landmark partnership marks a significant milestone for India’s engineering and process equipment sector.

First-of-Its-Kind Manufacturing License in India

Under the terms of the agreement, SGLTL has secured a 20-year license to assemble and market these advanced heat exchangers within India. This move makes SGLTL the first and only Indian manufacturer of these high-performance systems — a product segment previously entirely imported. SGLTL’s Managing Director, Nageswara Rao Kandula, emphasized the importance of the venture, noting its potential to reshape India’s thermal process solutions landscape.

Upgrading from Graphite to Glass-Lined Technology

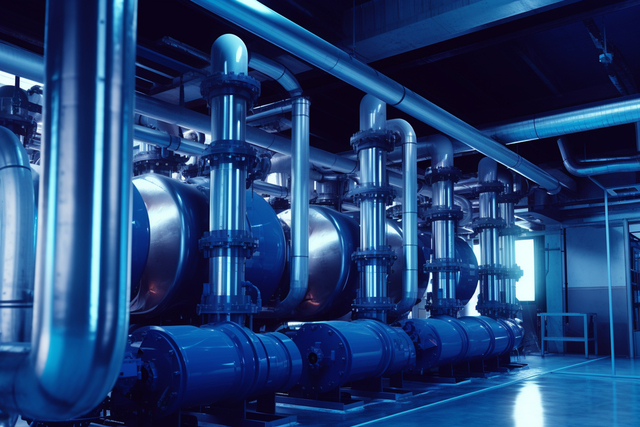

The new glass-lined exchangers are expected to significantly improve performance and reliability. They offer advantages over traditional graphite heat exchangers, which often cause particle contamination and batch failures. These problems are critical issues in the pharmaceutical and chemical industries. Thanks to their superior durability and enhanced safety, glass-lined systems will offer users a more dependable solution for high-purity and corrosive applications. This advancement will improve both operational efficiency and product integrity.

Strong Market Demand and Production Plans

SGLTL has already secured 150 advance orders, reflecting strong market interest in this upgraded technology. The company is targeting a monthly production capacity of 200 units by Q4 FY26, signaling robust scaling plans to meet anticipated demand.

Expanding Portfolio with Safety-Driven Innovations

In addition to heat exchangers, SGLTL will also manufacture conductivity glass-lined reactors. These reactors are designed to dissipate static electricity — a crucial safety enhancement for chemical and pharmaceutical plants. As reported by devdiscourse.com, the partnership localizes critical manufacturing. It also enhances India’s ability to produce advanced, globally competitive thermal process equipment.