Abstract

Waste is material which for some reason or the other we are not utilising back in our manufacturing processes. This article reviews how wastes can be extracted from effluent and other waters and utilised. Various valorisation methods are described and the process of how to go about it.

Manufacturing came into existence to produce goods and meet the requirements of humankind. Explosive population growth lead to increasing the demand of almost every material thing and this demand gave birth to industrialization. Industrialization helped to meet the increased demand however, the same Industrialization also excreted tremendous pressure on our natural resources such as clean Air and Water. Resource stressed scenario is seen worldwide. Majority of manufacturing processes generates wastewater with varying quantities and characteristics. Manufacturing puts pressure on water cycle in two ways:

1. Consumption of Fresh Water

2. Pollution in Water Bodies

In comparison to other fresh water consumers such as agriculture and domestic, consumption of freshwater by manufacturing industry is low but the toxicity of wastewater generated by manufacturing industry especially by chemical industries is very high. Manufacturing is necessary but at the cost of our natural resources? That’s today’s dilemma.

In case of water, there is always a pull between Industrial and Domestic demand. In most of the cases, the domestic demand is always given priority and water supply is restricted to Industry. This is the same picture for many years near the Industrial Belt.

Wastewater: It is really a Waste?

Waste is something which does not have any use and hence a commercial value. As per the conventional understanding, water generated during the course of manufacturing does not have value hence the same is termed as “Wastewater”. “Wastewater” needs to be “managed” with the lowest cost, as there is no possibility of revenue generation from the same. Reports indicate that pollution levels are increasing. Discharging of untreated wastewater in water bodies had been reported. Apathy by manufacturing industry towards Industrial Wastewater is turning Wastewater into a modern day evil and the cost associated with wastewater treatment is the cause of this apathy.

The question is “Is wastewater really a Waste?”

Waste is a limitation of our understanding or imagination. A Waste will remain as a waste until we find out a better use of it. Once it has a use, a waste will be converted into a value or revenue.

Long time ago, a black, oily and viscous liquid was discovered which we know today as crude oil. For a very long time, this black liquid was a source of nuisance and had very limited uses such as medicines and lubrication etc. By mid of 19th Century petroleum refining came into picture and the whole world found a new source of energy and raw material. Thus, a great technology is able to convert a Waste into Wealth.

Industrial Waste Water is another such resource, which is waiting for a correct technology for its transformation. Sustainability will assured when profitability is associated with wastewater.

In agriculture-based industry, many examples of Waste Valorisation can be seen and now a days they have been standard norms e.g composting, biogas etc.

However, the same concept is new in technologically advanced Manufacturing Industry.

Wastewater is a typically a mixture of various chemicals. Most of these chemicals are known. Interesting point to be notes that the chemicals, which are present in wastewater, have significant value/market price when they are present in pure form. However, in wastewater, because of the mixed nature, these chemicals lose their value.

Wastewater Valorisation aims at generating value from wastewater by three ways:

1. Recover Chemicals in pure form: Recovered chemicals can be recycled to the parent process thus reducing the cost of fresh chemical purchase or these chemicals are sold thus generating additional revenue

2. Reduce the cost of treatment: Once these chemicals are recovered, the treatment cost of wastewater reduces.

3. Reduce the cost of fresh water purchase: In cases where post chemical recovery water recycle is possible, the cost of fresh water can be saved.

Wastewater valorisation not only generates revenue from waste but also helps to minimize the environmental impact of toxic waste. Investment in Waste Valorization can give attractive payback. In few cases, estimated payback of 3 to 5 years is possible.

Present Waste Water Management Scenario

Today most of the technologies of wastewater treatment are cost centric. These technologies treat particular type of wastewater invariably resulting into a cost. Almost all newer technologies talks about how the latest technology will lower the cost in comparison to the existing technologies.

Lets take a closer look at the existing technologies which are considered as Industry Standards.

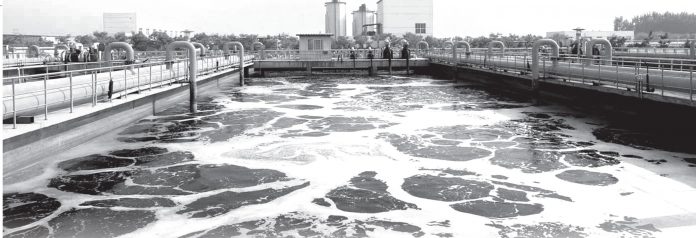

A. In a conventional biomass based systems, a low TDS & moderate COD containing wastewater streams are first conditioned for correct pH etc. The stream is then sentto microbes for consumption of COD and produce the biomass, which again has to be disposed off.

B. In case of wastewater streams with moderate concentration of dissolved solids, first, the stream goes to Reverse Osmosis for increasing the concentration of dissolved solids. The reject obtained goes to evaporation system. In case of high TDS stream, the stream directly goes to evaporation system. Evaporation System helps to recover water but in the process generates mixed salts. As the mixed salts does not have any value, they has to be disposed off to secured landfills.

C. In case of high Organics containing streams, the material is incinerated. Incineration process generates gaseous pollutants and residue/ash. Gaseous pollutants needs to be contained by absorption this generating secondary wastewater and residue/ash needs to be disposed off.

As can be seen, most of the present technologies convert one type of waste to other type of waste at the expense of energy. An unmanageable waste is converted to a manageable waste at cost. Since cost is a pain, many small scale industries could not afford these solutions and end up adopting “Short-Cuts”. Scenario of untreated wastewater going in water bodies are perfect examples of these “Short-Cuts”.

If technology can generate profit from wastewater then the same can become sustainable. Wastewater valorisation aims for the same.

Basics of Wastewater Valorisation

Step-1: Segregation of Wastewater streams:

As per the conventional treatment philosophy, all wastewater stream are collected in equalization tank prior to treatment. However this step is against the wastewater valorisation concept. Implementation of Wastewater valorisation after equalization tank create following technical difficulties

a. Concentration Reduction: Wastewater Valorisation Technologies are generally separation processes, which works better with higher concentration of targeted chemical. When the concentration reduces, separation before challenging thus increasing the operating cost of Wastewater Valorization Technologies

b. Increased Hydraulic Load: Post equalization, the composite stream volume goes up. Again implementation of Wastewater Valorisation Technologies after equalization leads to larger equipment resulting in higher capital expenditure.

Step-2: Complete Characterization of Wastewater:

Conventionally wastewater is the most neglected part of the manufacturing process. The wastewater is generally characterised from treatment point of view such as Chemical Oxygen Demand (COD), Total Dissolved Solids etc. In order to understand the value associated with the wastewater, its correct characterization i.e estimation of chemical composition and identification of chemicals present is wastewater is the deciding factor for successful implementation of valorization technologies.

Step-3: Identification of Correct Technologies

Wastewater valorisation technologies are separation process based on chemical engineering principles. Chemical Engineering Unit Operations are basics of Valorisation Technologies. Some of the examples of Wastewater valorisation technologies are as follows:

a. Selective Crystallization of Sodium Sulphate from Textile effluent

b. Selective Extraction of Acetic Acid from mixed wastewater streams

c. Recovery of Solvents from mixed solvents or wastewater

Large amount of literature is available which is published by Academia for chemical recovery from wastewater. A thorough literature search provide insight about the available alternatives for wastewater valorisation.

New Thinking

Conventionally the boundary of manufacturing ends at production of required material. Effluent treatment is a separate section in manufacturing setup and Production Team is not much concerned about the same. However, every Production Manager, Technical Team should look at Wastewater for its valorisation potential. Top Management of the manufacturing company, Manufacturing Heads, Effluent Plant Managers should look at wastewater stream closely and explore the possibility of valorisation. The strategic planner should choose sustainable Valorisation Technologies rather than quick-fixes such as Treatment Technologies.

Manufacturers producing similar products can join hand to create a Waste Valorisation Facility. This is particularly helpful for small-scale manufacturing companies. The partners along with the revenue generated can share the CAPEX burden.

Wastewater Valorisation has a potential change the approach of the manufacturing industry towards wastewater and make its management sustainable.