Abstract

It is important to reduce the use of petroleum products for vehicular transportation to reduce forex outgo as well as reduce carbon emissions. The government encouraging ethanol blending is welcome. However, ethanol only from sugarcane is not enough. Sugar beet is a feasible option to produce ethanol. This article highlights the importance of sugar beet for ethanol production which can be blended with fossil fuels. Importance, advantages and mechanics of ethanol generation from sugar beets are presented.

Importance of ethanol

India presently imports more than 220 million tonnes of crude oil and more than 32 billion cubic meter of natural gas per annum. The demand for crude oil and natural gas in India is increasing at 6 to 7% per annum, where as production is virtually stagnant. The outflow of foreign exchange due to import of crude oil is presently more than 27% of India’s foreign exchange earnings.

Under the circumstances, there is an urgent need to reduce the consumption of crude oil and natural gas in the country, to ensure energy security. While Govt. of India has taken a few initiatives to meet the impending energy crisis, one of the most important strategies of the government is to blend ethanol with petrol, that would reduce the consumption of petrol and consequently reduce the crude oil requirement.

Therefore, it is vital that the production of ethanol in India should be substantially increased for its use as fuel. Further, ethanol is also a strong building block for the production of a number value added derivative products. Therefore, boosting ethanol production as much as possible is the priority of need of the country.

Ethanol blending – Achievement & Target

In the current ethanol supply year (December-November), about 186 crore litres of ethanol have been blended with petrol until May 8, achieving around 10 per cent blending. Prime Minister has applauded the achievement of the target of 10% ethanol blending five months ahead of schedule. He further pointed out that in 2014, ethanol blending was only at 1.5%. Prime Minister said that 10% ethanol blending has led to the reduction of 27 lakh tonnes of carbon emission and has saved foreign exchange of Rs. 47,000 crore. Government of India has now set a target of 20% ethanol blending with petrol by the year 2025-26.

Requirement and availability of ethanol

NITI Aayog estimates the current annual ethanol production capacity at about 426-crore litre from molasses-based distilleries and 258-crore litre from grain-based ones. The production has to be increased to 760-crore litre and 740-crore litre respectively by 2025 to achieve 20% fuel blending – with 484-crore litres to spare to meet other needs. Considering the present status of new ethanol projects, the total capacity of ethanol is likely to increase to about 950 crore litres by December 2022 and 1,200 crore litres by December 2023.

Choice of feedstock

To boost the production of ethanol, Government of India has permitted ethanol production from different feedstocks such as C heavy molasses, B heavy molasses, sugarcane juice, sugar, sugar syrup, maize, damaged rice etc. India’s sugarcane acreage at present is around 46.67 lakh hectare. This results in sugarcane production of 430.5 million tonnes and sugar output of 35.5 million tonne. Even after the diversion of 3.5 million tonnes of sugar for ethanol production, there is a surplus of 8 million tonnes of sugar.

Sugarcane – Water intensive crop

Sugarcane is a water intensive crop. Water availability in India including surface water (river etc) and ground water is assessed to be around 1123 billion cubic meters. Central water commission has projected that India’s water need will increase from 634 billion cubic meters in year 2000 to 1093 billion cubic meters in the year 2025 and further to 1447 billion cubic meters in 2050. By then, Indian water requirement will exceed its resources. Out of the present water requirement in India, 85% of water is used for agriculture. Of this, sugarcane crop uses major share of water.

One tonne of sugar cane needs 60 to 70 tonne of water for cultivation. In Maharashtra alone, which is the major sugarcane producing state in the country, 71% of irrigation water is assessed to be used by sugarcane crop.

Therefore, it is clear that the consumption of water for sugarcane farming has to be reduced significantly. This, obviously, means that sugarcane farm area should not be increased and should preferably be decreased to a considerable extent. Under the circumstances, depending upon the sugar sector to boost the ethanol production in India in future to the level of future requirement of ethanol would amount to planning in vacuum.

Is it appropriate to use grains for ethanol production ?

To increase the production of ethanol, Govt. of India has permitted that grains such as maize, rice, etc can be used as feedstock for the production of ethanol. There is considerable criticism about this strategy of using grain as feedstock for ethanol production. Such criticism appears to be justified, since grains are food material. Further, grains are the starting material for the production of starch, which is the strong building block for the production of various value added products such as citric acid, L-Lysine and others. Number of such derivative products are presently not produced in India.

Therefore, a strong case exists to use such grains for the production of starch, which will lead to the production of several important derivative products. The criticism about the use of grains for the production of ethanol as a counter productive and short sighted approach appears to be appropriate.

Ethanol from Sugar Beet – Need of the day

Sugar beet is not only a source of sugar, but it also provides several by-products such as ethanol, pulp and leaves for cattle feed. Sugar beet contains 15 to 17% sucrose and in the process of sugar extraction, 12 to 14% of recovery is obtained. Sugar beet is cultivated in 41 countries in the world including Russia, Ukraine, France, Germany, USA, Egypt and others for the production of sugar and other derivative products. In view of the several compelling conditions in India, it is appropriate that sugar beet should be used as feedstock for the production of ethanol. Unfortunately, sugar beet is not presently produced in India on a commercial scale.

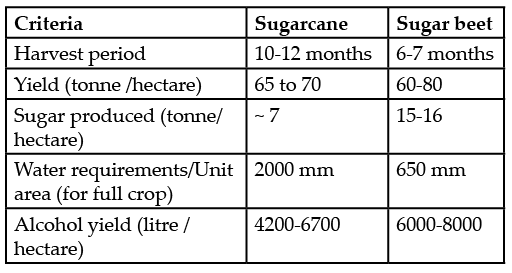

Sugar beet can be grown in black cotton soil. Since it is a salt tolerant crop, it can be grown in salty soil, where several other crops can not be grown. Sugar beet can also be grown in clay loam soil. Several regions in India are found to be suitable for sugar beet cultivation. The requirement of water for sugar beet cultivation is much lower than that of sugar cane cultivation and harvest time is much lower than sugarcane, as indicated by the following details.

Process for ethanol from Sugar beet

Process for ethanol from Sugar beet

Sugar beet has dry matter and high sugar content and therefore, quicker fermentation is possible. The initial operations for ethanol processing are washing of sugar beet roots, so that all the dust and mud particles are removed. The beet roots are thinly sliced into round pieces, which are known as cossettes. This process helps in extracting out the sugar content from the roots. The cossettes are dipped in hot water for juice extraction, after which the juice is fortified with nutrients. The adjustment of pH to 4.5 is required for lesser microbial. Sterilization of juice is the next step after pH adjustment, which requires a pressure of 15 psi for specific time. On cooling of the juice, the fermentation process is initiated by addition of yeast for the production of ethanol. Commercially available yeasts help in the conversion of glucose (produced after enzymatic hydrolysis through invertase enzyme) to ethanol, under an environment where oxygen is deficit. Anaerobic fermentation is responsible for the production of ethanol from sugar beet roots.

Half hearted measures

In India, trials on sugar beet cultivation have been carried out in different geographical locations including Karnataka, Maharashtra, Tamil Nadu, Gujarat, Uttar Pradesh, Rajasthan, Haryana, Andhra Pradesh and Telangana. Growing of sugar beet was tried at Indian Institute of Sugarcane Research (IISR), Lucknow and at Padegaon (M.S.) in 1960’s.

In 1970, the work was initiated under All India Co-ordinated Research Project (AICRP) on sugar beet. On the basis of agronomic trials conducted at various locations in India, sugar beet cultivation was taken up in Sriganganagar of Rajasthan for sugar production and in Sundarbans of West Bengal for alcohol production. A few other organizations such as Rana Sugars Ltd., Shree Renuka Sugar, Samarth SSK Ltd., Vasantdada Sugar Institute have also carried out several trials.

Although there are many advantages in favour of the sugar beet crop over sugar cane viz. short duration, less water requirement and potential for intercropping, yet issues regarding availability of seed of indigenous varieties, harvesting techniques, post harvest management have to be optimised. Though, development efforts with regard to sugar beet cultivation have been taken up several years back, the progress has been disappointing, possibly due to half hearted measures of sugar units and research bodies.

Need for policy initiative

Government of India’s policy with regard to boosting ethanol production has been dynamic and proactive. However, it is surprising that the feasibility of producing ethanol from sugar beet has not been given importance and such projects have not been implemented so far on a commercial scale.

Obviously, the government’s focus on ethanol production from sugar beet has been inadequate, in spite of its national importance. Considering the urgent need to increase the production of ethanol and limited alternative options available for boosting ethanol production, need for the ethanol from sugar beet must be recognised by the policy planners and stakeholders.

This is the subject where maximum focus has to be there by the government of India, just as in the case of renewable energy projects, electric vehicles and hydrogen economy. Need for ethanol production from sugar beet is no less significant.