Thyssenkrupp Uhde, a global provider of chemical technology solutions, has partnered with Novonesis, a pioneer in enzymatic technology, to launch uhde® enzymatic esterification.

The innovative process transforms ester production by significantly reducing energy consumption, improving product quality, and leveraging environmentally friendly biocatalysis at a competitive enzyme cost.

The Importance of Esterification in the Oleochemical Industry

Esterification plays a vital role in converting natural fatty acids into bio-based and biodegradable esters.

The esters are essential in a wide range of everyday products, including food, personal care, household care, and technical applications.

The new enzymatic esterification process replaces traditional inorganic or metal-based catalysts with bespoke enzymes from Novonesis, ensuring a more sustainable and efficient production method.

Enhancing Efficiency and Sustainability

Unlike conventional chemical catalysts, this enzymatic approach operates at much lower temperatures, leading to substantial energy savings and a remarkable 60% reduction in greenhouse gas emissions.

Additionally, the absence of chemical catalysts enhances safety by lowering operational risks and making the process inherently more sustainable.

Industry Leaders on the Innovation

Nadja Håkansson, CEO of Thyssenkrupp Uhde highlighted, “We are thrilled to introduce this enzymatic esterification technology in collaboration with Novonesis. This joint effort reinforces our commitment to sustainability while giving our clients a competitive edge with enhanced product quality and access to new bio-based markets. Together, we are shaping a greener and more efficient future in chemical production”.

Hans Ole Klingenberg, Vice President of Global Marketing, Industrial anf Household Care Solutions at Novonesis emphasized, “Our collaboration with Thyssenkrupp Uhde has enabled us to develop an advanced technology for producing low-carbon esters. By combining our enzymatic expertise with their process technology and proprietary equipment, we can achieve a new level of performance in ester production. We are excited to bring this innovation to the market together”.

Economic and Ecological Benefits

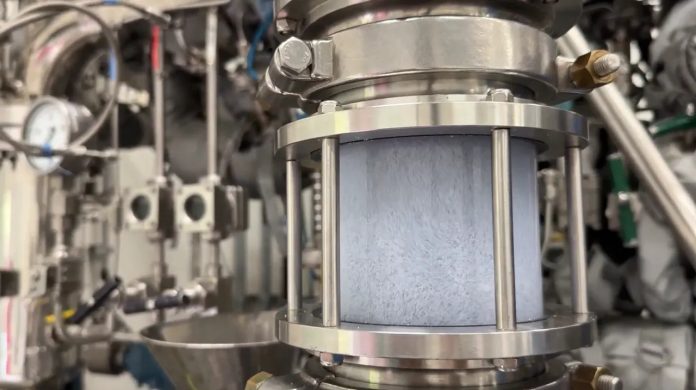

The proprietary reactor design and enzyme technology deliver high performance with minimal side reactions, reducing waste by up to 60%.

This not only improves the quality of the final product but also opens doors for new product development and market expansion.

Additionally, the specially designed enzyme bed enables up to 30 circulations per hour, ensuring high efficiency and cost-effectiveness.

The optimized process leads to shorter reaction times, higher annual production, and superior product quality, all while maintaining a competitive enzyme cost per ton of product.

Easy Integration and Retrofit Solutions

To support the transition to enzymatic esterification, Thyssenkrupp Uhde offers a retrofit package that enables existing plants to operate both conventional and enzymatic processes.

The flexible approach minimizes investment costs and risks while allowing businesses to quickly enter the sustainable products market. Successfully tested in a pilot plant, the technology is now ready for scale-up and industrial application.

As per the press release, Thyssenkrupp Uhde and Novonesis are combining their expertise to drive the future of ester production. Their solution is sustainable, efficient, and cost-effective. It benefits both businesses and the environment.